Miscellaneous inspection system

Overview

Surface inspection technologies can be applied to various types of materials with flat surfaces such as acryl products, nonwovens, and building materials.

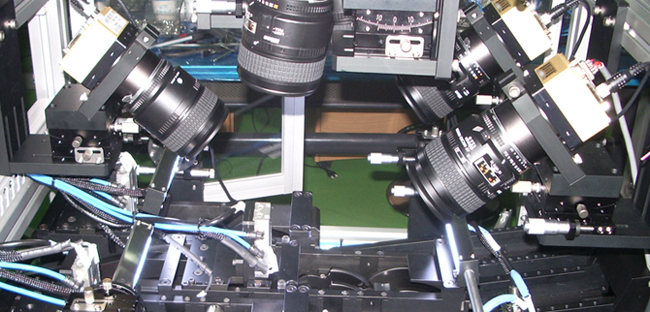

The ideal combination of lighting and camera systems can be configured to help identify defects from normal product patterns.

Features

• Provides superior detection performance through various optical technologies

• Enables convenient lot management (data such as inspection roll length / inspection duration /

worker / defect type can be saved and checked later.)

• Maintains inspection precision while product feeding speed changes

• Utilizes results through various communication channels

• Saves and prints all images of defects

• Performs defect trend analysis and generate statistical reports

• Generates various types of defect detection reports

• Displays defect distribution in real time

• Displays defects in multiple ways, such as with alarm/buzzer/labeler/marking device

• Automatically screens out defect products during individual product feeding

Specification

Item | Specification | ||

|---|---|---|---|

Vision system | Camera | Lens | Illumination |

4K, 6K, 8K Linescan | 35mm, 50mm, 60mm, 80mm | LED, Hologen, High frequency FL | |

Inspection targets | Acryl plates, nonwovens, building materials | ||

Product types | roll to roll or sheet | ||

Product specification | Width of product, feeding speed | ||

Defect types | Bubble, foreign substance, scrap of thread, pinhole, stain, scratch | ||