Bioplastic (ES-2125T)

You can see more than 4,000 tons of local plastic disposal per year on the basis of 2003.

The amount of recycled quantities is one third of the total, and the remainder is incinerated or landfill.

The fossil-based product cause environmental pollution and harmful gases during incineration.

Therefore, biobased plastic products manufactured by Synthetic chemical or biological method is getting closely related to human life.

Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, or microbiota.

Bioplastic can be made from agricultural by-products and other containers using microorganisms.

However, Kindred products with many advantages have some problem with physical property such as decline of productivity, weak dispersibility and low tensile strength, when by-product is added over 5% during manufacturing precess. We developed effective methods for using large quantities of starch. We use rubber and HDPE of which minimum biobased content is 96%, determined according to ASMT D6866. The film produced from this resin has high tenacity and excellent resistance to impact characteristics.

This resin has wide molar mass distribution that makes it easier to process.

They make biomass content up to 25%. This product applies to film and sheet for bags, trays, fruit and vegetable containers.

ES-2125T (for sheet) / ES-2120F (for film)

• Excellent physical property

• 100% recyclable

• Usage: Shopping bags, envelopes, food packaging, trays, etc.

• HDPE/LDPE

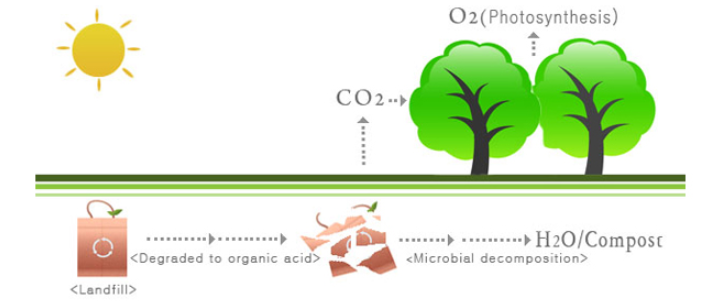

• Rapid degradation speed by sunlight, moisture, and micro-organisms.