Liquid Warm-Mix additive [ECON WM1-200PL]

- This product can be used for wide temperature range from 100℃ to 130℃. At the same time,

economic benefits from energy saving and the reduction of greenhouse gas emissions are also achieved.

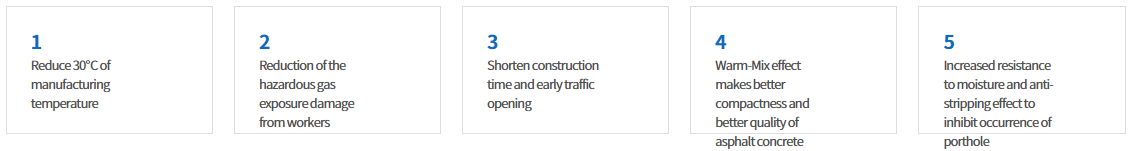

Warm-Mix asphalt additives of NH Corporation can lower the working temperature by 30℃ while maintaining the quality as good as hot-mix asphalt mixture.

This product can be used as Hot-Mix asphalt mixture, ECOM WM1-200PL has the function of anti-stripping.

How to use | Storage | Physical properties | |

|---|---|---|---|

Test item | Test result | ||

When applying ECON WM1-200PL, utilizing a specially designed feeding device can be very good for workability. | Please keep at 0 ~ 30℃ | Amine value | 85~115mgKOH/g |

Viscosity(25℃/CPs) | 1000 ~ 3000 | ||

Specific gravity(25℃) | 0.93 ~ 0.99 | ||

Appearance | Yellow, liquid viscous | ||

Flash point | > 190℃ | ||

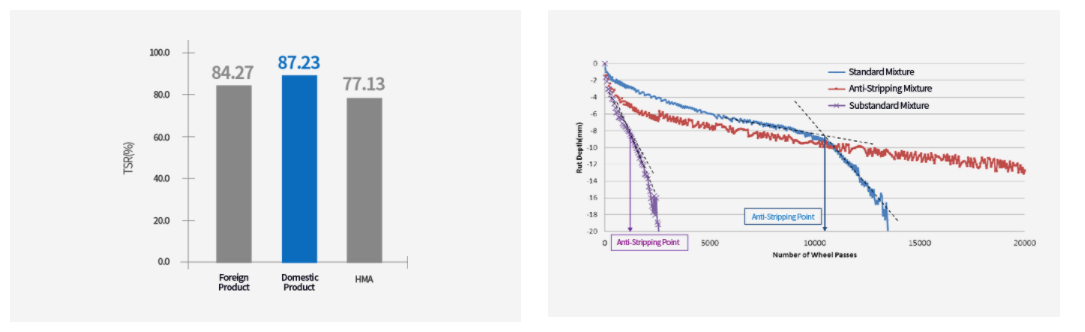

● Performance evaluation of ECON WM1-200PL

-TSR Test & Hamburg Wheel Tracking Test

▶ The test is based on KS F2396(Standard practice for recovery of asphalt from solution using rotary evaporator)

▶ The test of tensile strength from external shock to mixture. (moisture & unpollinated treatment)

▶ The mixtures which are used for surface and middle layer have to be over 80% of TSR. If they are not on that spec, anti-stripping additive must be used.

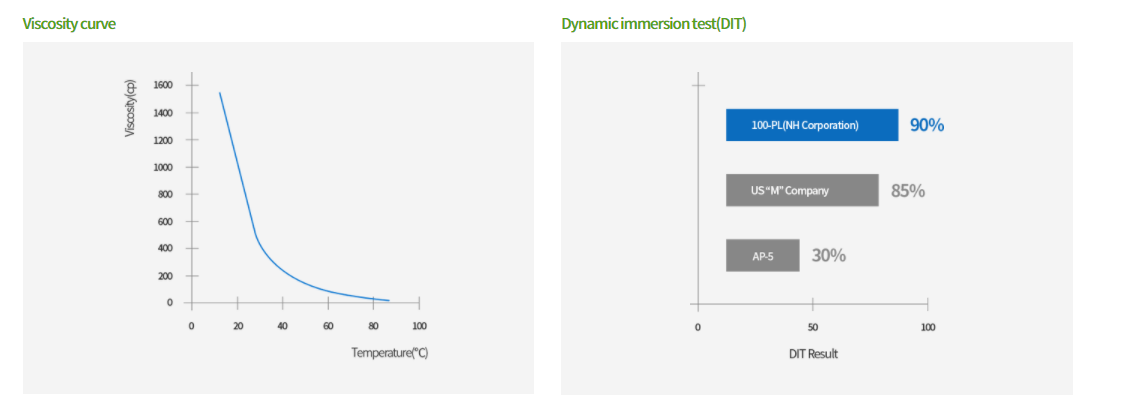

● DIT Test (Dynamic Immersion test)

▶ This test is based on European Standard (EN-12697-11). Determination of the affinity between aggregate and bitumen.

▶ The method of test : Using the coated aggregates put into 25℃ water, and spin on 60 rpm for 6 hours and 24 hours. Check conditions of aggregates.

▶ If they are under 50%, anti-stripping additive must be used. (Standard of Ministry of Land Korea)

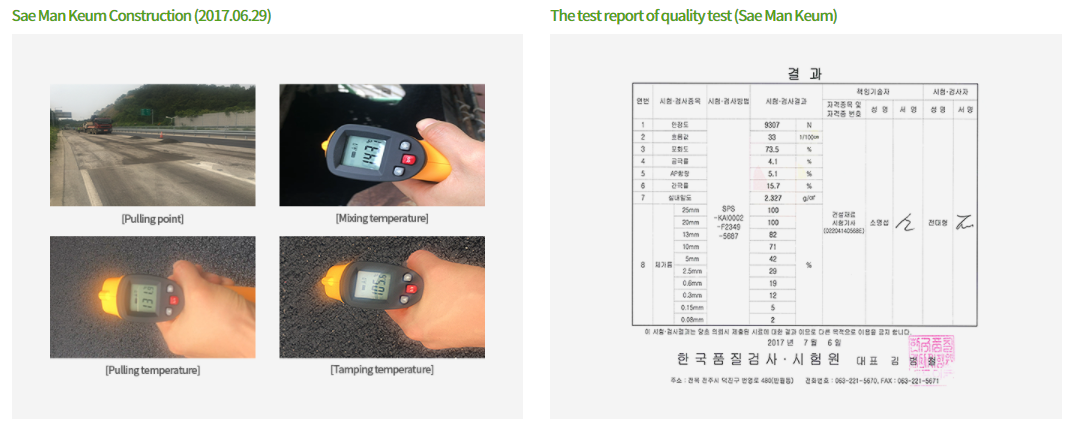

● Construction case of Warm-Mix [ECON WM1-200PL] I

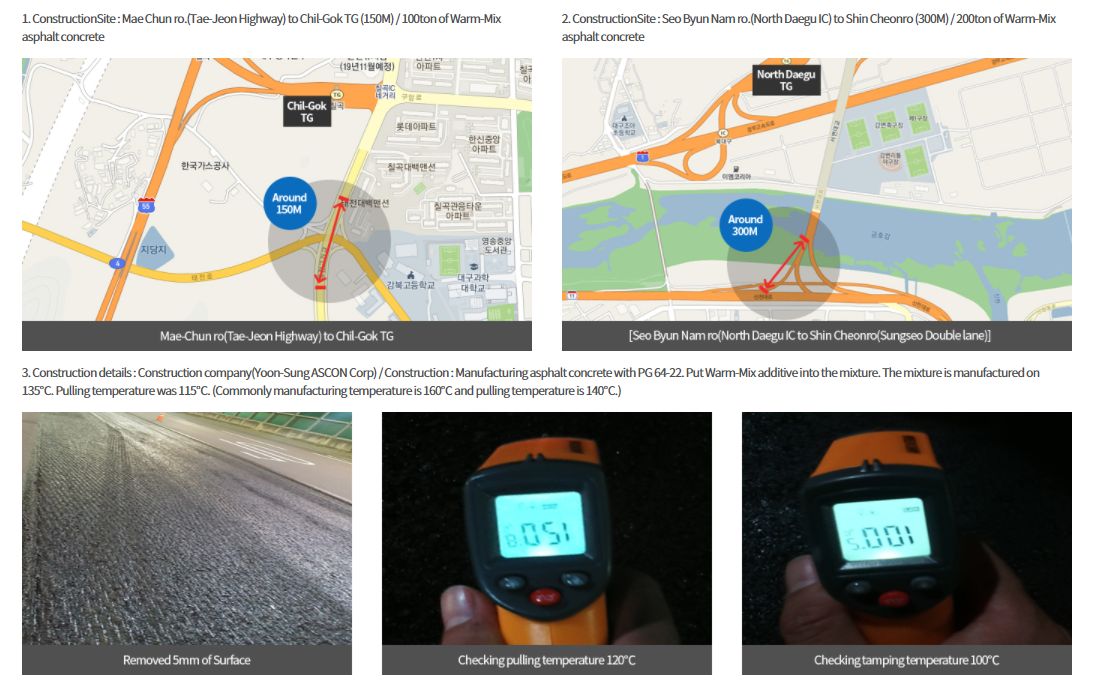

● Construction case of Warm-Mix [ECON WM1-200PL] II

- Daegu Metropolitan Facilities Management Corporation

▶ The pulling site, where has big traffic is chosen by Daegu Metropolitan Facilities Management Corp. The reason is Warm-Mix additive has a function of anti-stripping.

▶ Pulling time :: 6 hours 30 minutes.(Started at 22:00 on 24th, Ended at 05:00 on 25th)

▶ Amount of using Warm-Mix additive : 72Kg (Dosage : 0.6% of asphalt)

● The expectation and environmental effects of ECON WM1-200PL

-Environmental effect of ECON WM1-200PL

▶ For road pavement, compared to Hot-Mix asphalt concrete when Warm-Mix with NH's additive.

There is reducing effect of NOx(nitrogen oxides), SOx(Sulfur oxides) and fine dust in the air.

▶ In Korea, there is reducing effect of 73.4% carbon monoxide, 72% nitrogen oxide and 41.7% sulfur oxides when Warm-Mix pavement.

▶ In foreign, there is reducing effect of 77% fine dust when Warm-Mix pavement.

-Reduction of Effluent gas

Effluent Gas | HMA (Hot Mix Asphalt) | WMA (Warm Mix Asphalt) | Reduction Ratio(%) |

|---|---|---|---|

CO2 | 3.2 | 1.9 | 40.7(↓) |

CO(ppm) | 983 | 262 | 73.4(↓) |

NOx | 75 | 21 | 72(↓) |

SOx | 60 | 35 | 41.7(↓) |

Fuel(l/ton) | 9.3 | 6.3 | 32.3(↓) |

● Comparative analysis between Liquid type and Powder type additives

Division | Liquid Warm-Mix additive (NH) | Powder Warm-Mix additive | ||

|---|---|---|---|---|

Input Method | Plant mix | Needed injection equipment.(about $13,000), Input A/P measuring tank | Plant mix | Needed exclusive silo(around $40,000), |

A/P Pre-mix | Applicable(Hyundai Oil bank, GSC : now on testing) | A/P Pre-mix | Non applicable | |

Input | 250 ~ 300g per 1ton of asphalt concrete | 1KG per 1ton of asphalt concrete | ||

Economic feasibility | Price : 9,000won/KG, | Price : 3,100won/KG, | ||

Working environment | Reduction effect of 77% fine dust | Powder state with lots of dust Poor working environment | ||

Usability | Ease of use when applying to Pre-mix | None applicable to A/P Pre-mix | ||

Performance | Liquid type additive has better jet force than powder type. | Powder type has worse get force than liquid type. | ||