Fusion®HR

▶ General

- Fusion HR (High Release) is our sol-gel ceramic coating, which maximizes the release life and properties of any solgel ceramic coating.

Sol-gel coatings for cooking surfaces are typically extremely hard and thermally resistant, colorful with glossy surfaces.

The main disadvantage recognized by the users of sol-gel coatings is the premature loss of release of these coatings.

Fusion HR (High Release) addresses this.

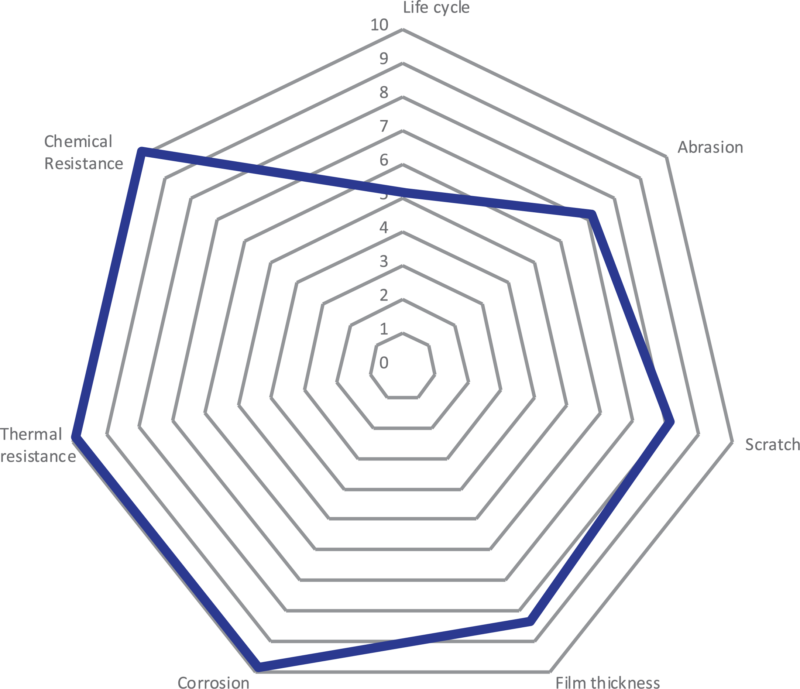

The remarkable nonstick performance of Fusion HR has been demonstrated via two extremely harsh tests, Whitford’s Thermal Stress Test and Whitford’s Chemical Stress Test. In both cases, Fusion HR signifi cantly outperformed other traditional ceramic coatings.

Fusion HR offers release properties previously thought to be unattainable in a sol-gel ceramic nonstick coating.

● Characteristics

▶ Fusion nonstick coatings have achieved FDA’s concurrence that there would be no health or safety concern with the use of the product and that Fusion nonstick coatings are exempt from FDA regulation. Fusion has been evaluated by a legal third party to ensure compliance with EU food contact regulations.

▶ nonstick performance outperform other traditional ceramic coatings in Whtiford’s Thermal Stress test and Chemical stress test.

▶ offers excellent release properties previously thought unattainable in sol-gel ceramic coatings

▶ made without PFOA and PTFE

▶ excellent stain resistance

▶ ideal for browning and searing.

▶ more environmentally friendly because it cures at a low, energy- saving temperature.

▶ continuous use temperature of and is oven safe to 285°C/550°F. NOTE: This only applies to the coating. The continuous use temp of the other components of the finished product must also be considered.

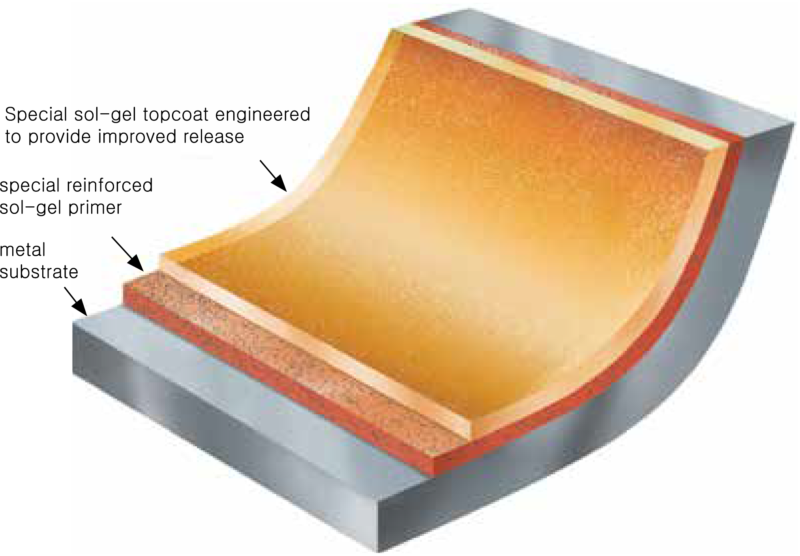

▶ If using an active Whitford QCP approved factory, the logos and the cross-section illustration shown here are available for use on any promotional/packaging material.

● Logo Options

● Color

▶ variety of colours available, including spatter finishes

▶ darker colours recommended.

▶ lighter colours can have an impact on performance, in regard to hiding power, stain resistance, or slight variations in other characteristics, as a result of pigment load required for other formulating factors.

● Notes

- The performance data listed above is dependent on the coating being applied as per the parameters listed here and the criteria set on the Product Data Sheet for each coating. Proper application, including proper film thickness, surface preparation and cure, are critical to this coating performing as it has been designed. Corrosion resistance will be optimum with all multi-coat nonstick systems, with proper application, as mentioned above.