COLOR MADE

● What is COLOR MADE?

- Each plant has a green pigment called chlorophyll, a red color pigment called anthocyanin and an orange pigment called carotene.

These pigments are involved with each other to produce color. These pigments are expressed by light, temperature and sugar.

The most important thing among them is light, even UV rays to decide the coloration of fruit.

However, light and temperature are bound to be conditioned in the natural domain, but the sugar's factors can make a difference depending on the effort. After cell division, it is necessary to minimize the loss of sugar consumed by photostimulation in the body by maximizing photosynthesis.

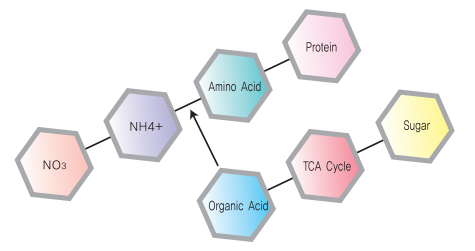

The intake of nitrate and ammonia nitrogen into the plant at the harvest time consumes the organic acid that is made with the sugar to produce amino acids which makes it difficult to improve coloration and sugar content up.

● Main Active Ingredients

▶ Garlic Extract 5%, Seaweed Extract 14%, Polysaccharide 12%, Methionine 2%

● Effects

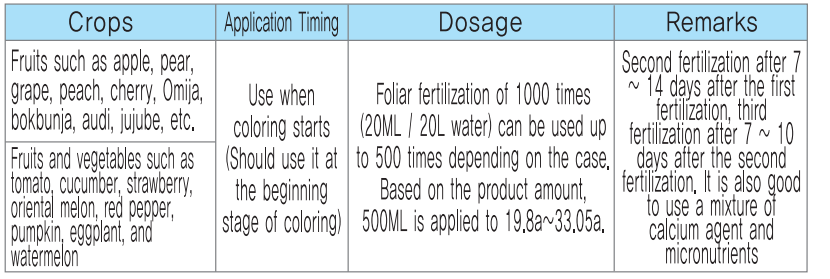

1) When you use it to express the unique pigment of fruit, the red becomes clearer and the green becomes darker.

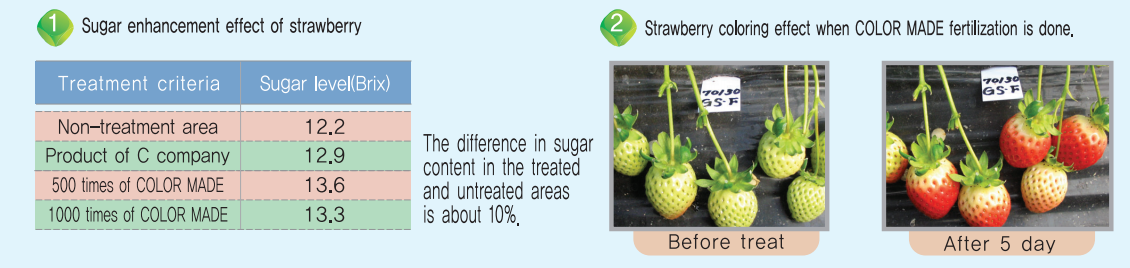

2) It improves marketability when Increased sugar content and early harvest are needed

3) If you use it when the fruit is not colored smoothly due to inclement weather, lack of sunshine, it will help quick coloring.

4) When you use it when the coloring is uneven and density is weak due to the large amount of water to be transported,

it helps coloring by recovering density.

5) The unique fragrance of the product reduces the damage caused by algae and pests that are common in the harvest season.

● How to use

● GUARANTEED ANALYSIS

▶ K2O 5.0%

▶ B2O3 4.5%

▶ Zn 0.6%

- The coloring usually starts 6 weeks before harvest and starch begins to turn into sugar.

At this time, mixed fertilizer of calcium and coloring agent is effective to enhance the storage stability and prevent sugar loss.