Metal Carboxylates

- Metal carboxylates are chemical substances consisting of metal and the long-chain fatty acid.

The catalysis of the metal is applied and used as a curing promoter and adhesion promoter.

Metal carboxylates acts an accelerator of the chemical reaction.

The metal carboxylates are used in various applications.

Key properties include its beneficial characteristics as organic metal compounds.

● About Metal Carboxylates

- Introducing various functions and mechanisms of the metal carboxylates for practical applications;

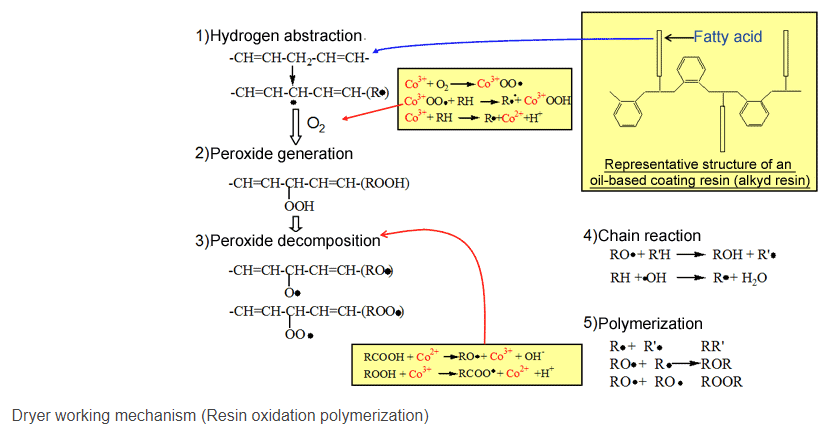

▶ Drying Acceleration(Dryer) :

-Metal carboxylates added to drying oil coatings and printing inks, with air drying alkyd resin as the primary ingredient, will accelerate oxidation polymerization to accelerate the curing (drying) of the coating film.

There are a number of types of metal carboxylates that are normally combined and used.

Dryers primarily promote 1. double-bond α-Methylene hydrogen abstraction and 2. decomposition of produced peroxide and work to accelerate resin polymerization.

▶ Reaction Acceleration

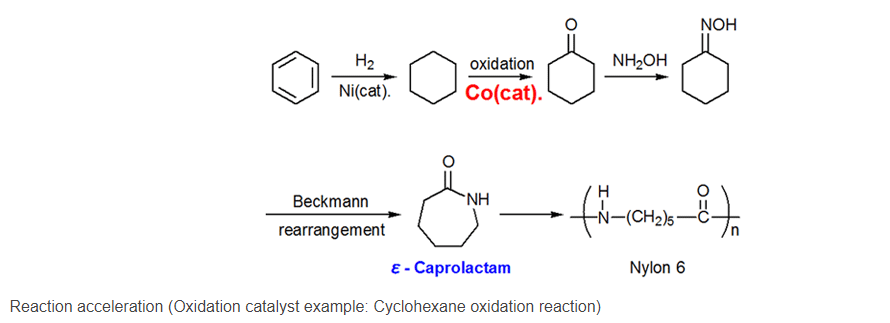

- Cobalt carboxylates are used in various organic synthetic catalysts as an oxidation catalyst.

For example, cobalt carboxylates are used as an oxidation catalyst when manufacturing cyclohexanone,

an ingredient in caprolactam which is the base for nylon 6, by direct oxidation of cyclohexane.

Cobalt and nickel carboxylates are also used as polymerization catalysts for butadiene rubber.

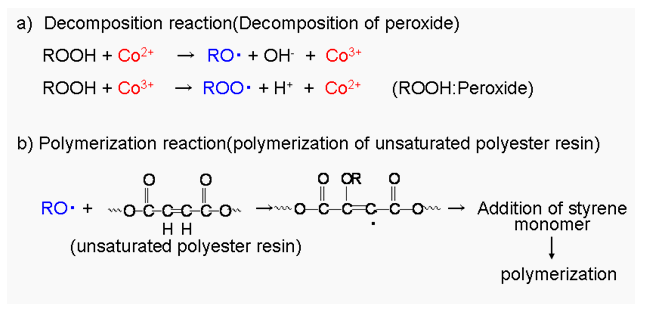

▶ Cure Acceleration

- Cure acceleration of unsaturated polyester resin combined with radicalized organic peroxide becoming a cross-linking agent.

Cobalt and manganese carboxylates work to accelerate resin curing by accelerating organic peroxide decomposition (radicalization).

● DIC's Advantages

- Introducing the advantages of DIC's metal carboxylates;

▶ High Japanese Market Share, Broad Product Lineup :

DIC maintains high market share in the Japanese domestic metal carboxylates market which includes coatings and printing inks.

DIC is also expanding globally in the tire industry.

DIC has a full product lineup of various kinds of metal carboxylates including cobalt-based products that meet specific customer requirements.

▶ Design Expertise/Responsiveness to Create Function According to Need :

DIC is actively working on an approach to environmental responsiveness.

DIC is currently developing water soluble metal carboxylates and non-aromatic solvents.

DIC can customize diverse products that meet the demands of our customers.

▶ Domestic & International Production Sites :

DIC's metal carboxylates are produced at two sites, the DIC Kashima Factory (Kamisu City, Ibaraki Prefecture, Japan) and DIC Synthetic Resins (Zhongshan, China), and these sites are supplying products to the world. Both factories obtained ISO certification rapidly.

We are supplying top quality products and are continuing safe operations.

● Major Applications

- The catalysis of the metal is applied, and it is used for various applications.

▶ Driers for paints and printing inks :

It is used as curing agent of paints such as alkyd resin paint and printing inks.

▶ Unsaturated polyester accelerator :

It is used as a accelerator of unsaturated polyester resin which is used in the manufacturing of bathtubs and decorative boards; initiating radical polymerization.

▶ Urethane catalysts :

It is used as a curing agent of polyurethane which acts as a waterproofing layer and barrier.

▶ Additives for lubricating oils and greases :

It is used as extreme pressure additives and rust preventives of metal working fluid and grease.

▶ Catalysts for organic reactions :

It is used for the polymerization reaction such as synthetic rubber and the oxidation synthesis of various reactions.

▶ Fungicides and Wood preservatives :

It is used as the wood preservative and fungicides of electric wire coating.

▶ Steel cord-rubber adhesion promoters(for tire) :

Cobalt carboxylate is used as a adhesion promoter of tire rubber to the steel core.