VCI POWDER

Overview of RUSTEC VCI Powder

● Overview

- VCI Powder prevents metals from corrosion and protects metals deep in a metallic container, a hole, or an internal crevice.

VCI vapors in a sealed space may form a monolayer that is invisible on the metallic surface.

These vapors can prevent rusting by blocking metallic ions from reacting on water and oxygen.

In addition, as vapors do not lose the properties in water, they can be utilized as a dry or wet method.

● Features and Advantages of RUSTEC VCI Powder

▶ Features and Advantages

- RUSTEC VCI Powder does not affect primary properties of metals and can function as an anti-rust agent even in fine areas in a corner where human hands cannot reach.

- Since its effects last long. there is no need for refilling. Even if the vapor balance is collapsed due to a temporary opening.

its anti-rust effect continues owing to its self-compensating property.

- Although it is not necessary to remove the powder to use a product, the powder is easily removable with air or water.

- It does not need advance preparation on the metallic surface.

- Chemicals in it are used as food additives. Silicon salt, phosphate, or heavy metals are not contained.

- It can be used in a water-soluble form.

- These products have passed the SGS RoHS TEST (EU Restriction of Hazardous Substances Directive).

● Use of RUSTEC VCI Powder

▶ How to Use

- When applied in powder form, it should be used in an evenly distributed arrangement using a low-pressure sprayer, etc, and if VCI powder is not appropriate to use, products in the form of a pouch can be applied in an evenly distributed arrangement, After being applied, it should be sealed tightly as soon as possible.

- Within 30 centimeters easy for vapor to be reachable, VCI powder or items wrapped with non-woven cloth should be dispersed.

It is the most effective way to arrange VCI powder evenly in a space to prevent metals from rusting.

Arrangement in an even distribution in a space leads VCI compounds to reach the metal surfaces fast and distribute evenly in the space, which can reinforce anti-rust effects. If it is hard to arrange VCI powder evenly in a space, it can be the next best plan to place it from the top in the space because the gravity of vapor is heavier than air.

In case it is inevitable to arrange it on the floor, it is also effective to place it on the floor in an even manner.

- In a water pressure test, dilute it at the rate of 1 to 3% of the water weight.

- The quantity consumed may be different depending on the corrosion inhibitor period, packing method, packing material, temperature, humidity, excessively large surface of the target metal (powder or small grains saturated in the package). or sealing condition. Normally. 50 to 250g would be appropriate per 1m (CBM) However, the quantity consumed may increase depending on using condition.

• Types and Applicable Areas of RUSTEC VCI Powder

▶ Product Types

- RUSTEC PDM-100

: Common-use powder - ferrous metal (carbon steel), non-ferrous metals (aluminum, copper, copper alloy, etc.)

- RUSTEC PDF

: Powder for iron-ferrous metal (carbon steel)

▶ Applicable Areas

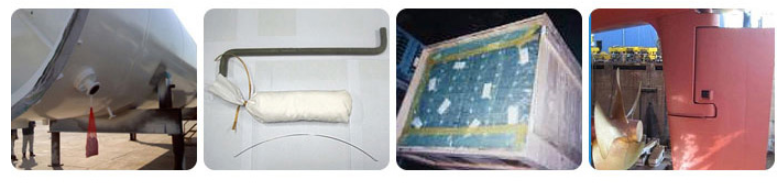

- Plant production, shipment for export, storage, and transportation

- Internal surfaces of a piping structure, radiator, boiler, engine, tank, motor, etc. .

- For hydro testing (water pressure test) of a pipe. heat exchanger, cooling recirculator, boiler, or tank

- Closed recirculating cooling systems

- Box packing of tools and various parts: piping, container export, storage, etc

- Inside a ship rudder, void, etc.

• Product specifications and Storage of RUSTEC VCI Powder

▶ Product specifications

-Packing unit: 10kg. 25kg (aluminum bag, fiber drum) / 2.5g, 5g. 10g. 30g, 50g, 100g, 500g pack type (pouch)

▶ Storage

- Avoid direct sunlight and humidity. Seal the package before storage.

▶ Corrosion inhibitor period

- 1 year or longer (The period can be extended depending on the level of sealing.

As to inside rudders, semi-permanent protection is possible.)