VCI LIQUID

1. Introduction to LFD-101

● Overview

- RUSTEC VCI Liquid LF D-101 is a liquid type of highly-functional Volatile Corrosion Inhibitor that can reach areas where a general liquid type anti-rust agent can hardly reach.

This high-performance VCI Liquid starts to have a successful corrosion inhibitor effect when exceeding the level of 0.1% concentration.

In experiments, cold rolled steel plates did not become rusty at all when remaining dipped in tap water (99.9%) for 1 month.

It is applicable to various areas since it secures additional lubrication and cleaning functions in addition to the basic corrosion inhibitor function.

This product can be used for areas where anti-rust oil or grease cannot be used.

This product for ferrous metals also can be used as a short-term alternative anti-rust agent, as a corrosion inhibitor in a sealed area or for hydro tests, and as an additive for water-soluble metal processing oil.

● Features

- Since it is highly-enriched solution, a small quantity of this product may be used for dipping.

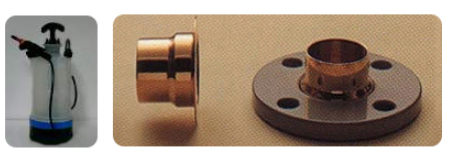

- It can be used for water pressure testing of tanks, pipes, boilers, etc.

- As it is water-soluble, post-treatment is simple,

- It can be used as a corrosion inhibitor additive for water-soluble metallic processing oil.

- It contains no harmful substance such as phosphate, silicon, DICHAN, etc.

● Applications

- Corrosion inhibitors for closed cycling type cooling systems.

- Internal/external corrosion inhibitors for tanks, gauges, boilers, plants, pipes, etc.

- For metallic construction materials.

- For water pressure testing of circulatory radiators, heat exchangers, tanks, vessels, boilers, etc.

- Additive of water-soluble metallic processing oil or water-soluble refining oil in a limited range

● How to Apply

- For water pressure testing or dipping, the proper range of concentration is 0.2 to 1,0% (recommended concentration).

It may be diluted with tap water or industrial water. However, it may be used at a lower or higher concentration than

the recommended concentration based on on-site testing results.

- In the case of internal corrosion inhibition, the volatile material remains even after diluted liquid discharge unlike ordinary liquid corrosion inhibitors. The higher concentration, the more effective.

- pH should be kept at least 10.0 at the site. If pH is low, increase the quantity of LF D-101.

● Packing standard

- 20kg Pail, 200kg PE drum

- Put it in a container and keep in a cool and dry place. Be sure that it is not exposed to direct sunlight.

2. Introduction to LM S-100

● Features

- For spray on ferrous and non-ferrous metals or for dipping

- As an additive when VCI Films are used

- As it is water-soluble, post-treatment is simple.

- As a corrosion inhibitor for tanks and pipes

- It contains no harmful substance such as heavy metals

● Overview

- RUSTEC VCI Liquid LM S-100 is a liquid type of highly-functional Volatile Corrosion Inhibitor that can reach areas where a general liquid type anti-rust agent can hardly reach. This can be used as an additive of corrosion inhibitors when anti-rust oil or grease cannot be used or for temporary corrosion inhibition effects or in a closed space.

● How to Apply

- Use about 200ml of the undiluted solution per 1m².

- For leak testing, you may dilute it with water. When used in a closed space, the corrosion inhibitor is more effective.

- Be sure that there is no lost corrosion inhibitor due to rain or snow.

● Applications

- Inter-process or final corrosion inhibition

- Internal/external corrosion inhibitors for tanks, gauges, boilers, plants, pipes, etc.

- For metallic construction materials

- Leak testing for tanks, etc.

- Applicable to corrosion inhibitor boxes or sheets as it is sprayed on boxes or sheets.

● Packing standard

- 20kg Pail, 200kg PE drum

- Put it in a container and keep in a cool and dry place. Be sure that it is not exposed to direct sunlight.

3. Introduction to LM D-200

● Overview

- RUSTEC VCI Liquid LMD-200 is a liquid type Volatile Corrosion Inhibitor applicable to carton boxes and kraft paper. It is used to produce corrosion inhibitor carton boxes and VCI Paper.

● Features

- Applicable to ferrous and non-ferrous metals.

- Water soluble: high workability

- Highly absorptive: it is possible to mass-produce VCI Paper.

- It contains no harmful substance such as heavy metals

● Applications

- Applicable to carton boxes and kraft paper for corrosion inhibitor carton box and VCI Paper production.

● How to Apply

- Use it as undiluted solution.

- When applying it to carton boxes and kraft paper, use about 15 to 20g per 1m2,

- The corrosion inhibition performance is effective even when it is sprayed in a paper type packing material.

● Packing standard

- 20kg Pail, 200kg PE drum

- Put it in a container and keep in a cool and dry place. Be sure that it is not exposed to direct sunlight.