PBI

- With a pyrolysis temperature exceeding 600℃, PBI provides a heat distortion temperature (HDT) of 410℃, and glass transition temperature (Tg) of 427℃, making it an extremely high heat resistant resin available on the market. It is gaining attention as a material that can be safely used in the applications that have been difficult with the conventional resins due to its thermal, mechanical, and electrical properties, and can replace carbon, C/C composites, ceramics, and metals.

● Major Properties

① Thermal characteristics - Uultra heat resistance, low expansion rate, low thermal conductivity

② Mechanical properties – High strength, high hardness, tensile strength of 160MPa

③ Electrical properties – Selectable from insulation to conduction

④ Sliding properties – Wear resistance, low friction coefficient

⑤ Chemical resistance – Strong resistance to organic solvents such as acids and bases

⑥ Plasma resistance – Good plasma resistance, stable strength even after 120MGy irradiation

● APPLICATION

▲ General industrial

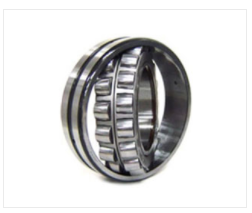

Applicable products: industrial rotors, bearings, etc

▲ General industrial

Applicable products: industrial rotors, bearings, etc.

▲ Semiconductor / for manufacturing FPD

Applicable products: Semiconductors, Eqipment components of a liquid crystal vacuum device

▲ Semiconductor / for manufacturing FPD

Applicable products: Semiconductors, Eqipment components of a liquid crystal vacuum device

▲ For motor use

Applicable products: Thrust washers, Seal rings, Valve seats, Bushings, Washers, Thrust Plugs, Anti-lock braking system, Wear pads, Fuel sytems, Turbo chargers, Etc