Meta Aramid

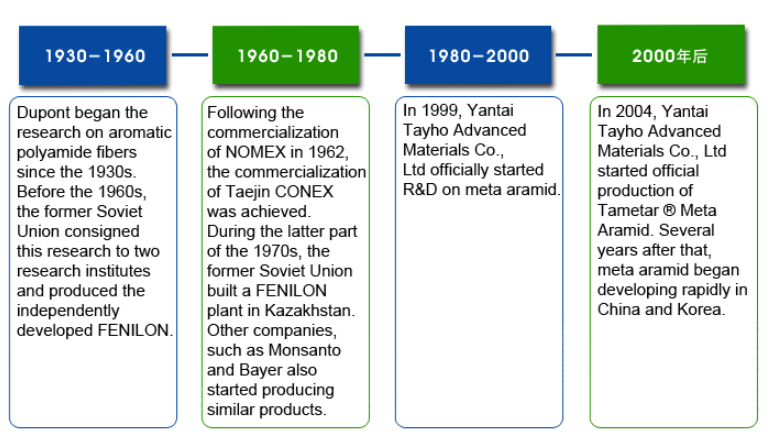

● Tametar® Meta aramid development history

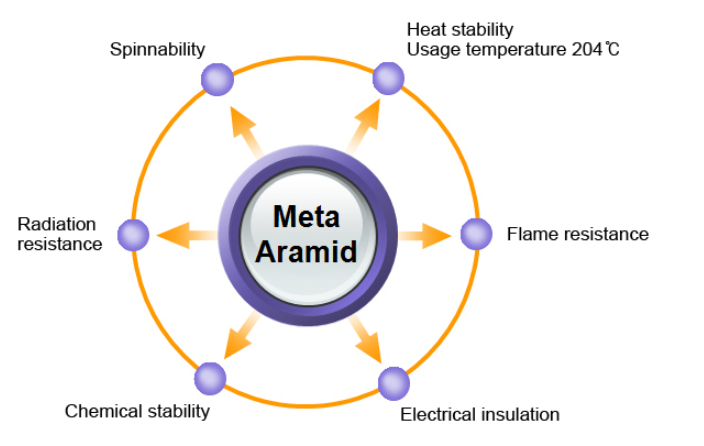

-With amine acyls and meta phenyls connected as linear macromolecules, the structure of meta aramid is flexible. In addition, the chemical structure is very stable as a result of the effects of hydrogen bonding and benzene rings.

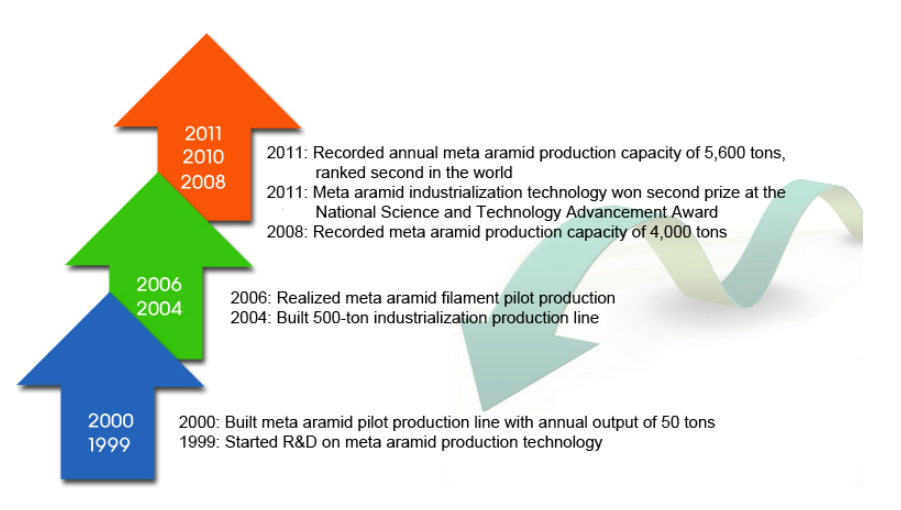

▶ Tametar® product development history

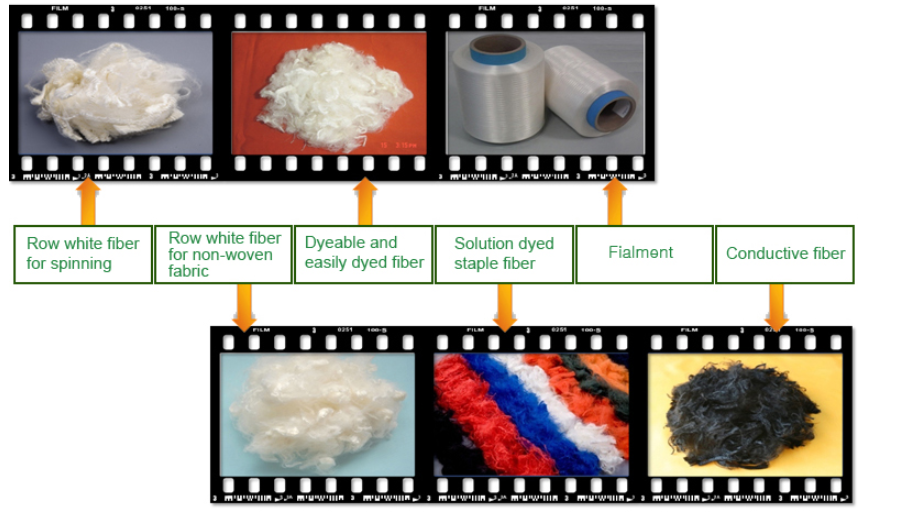

▶ Tametar differentiated products

● N600 – Fiber for spinning & Solution dyed staple fiber

▶ N600 – Row white fiber for spinning

- Various fiber types

- Specifications fully completed

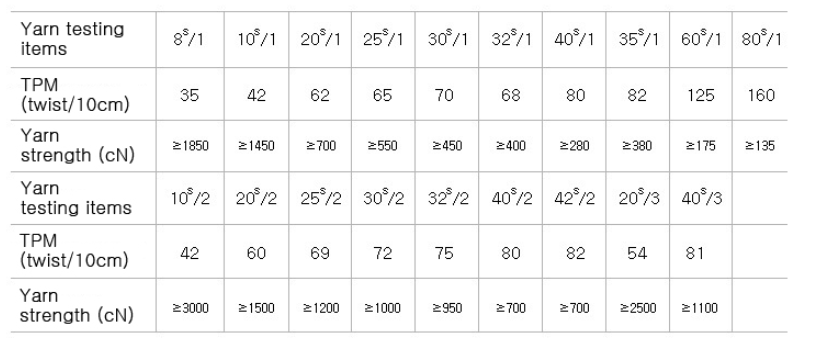

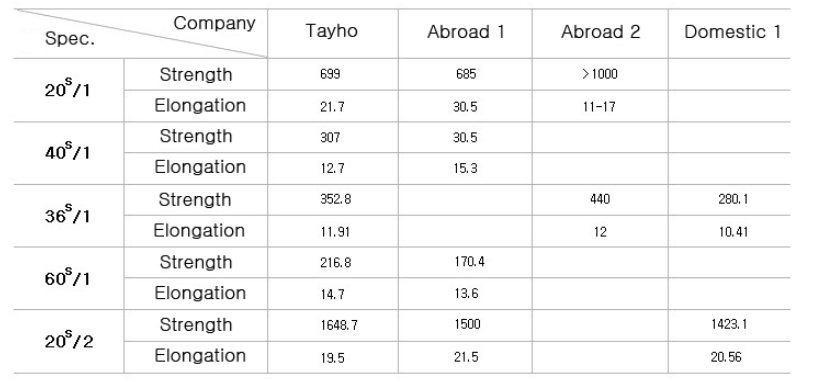

- Excellent yarn performance and outstanding strength

- Outstanding strength of textile

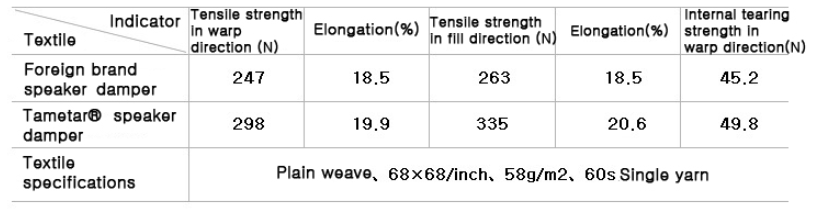

Compared to speaker damper strength

▶ Solution dyed staple fiber

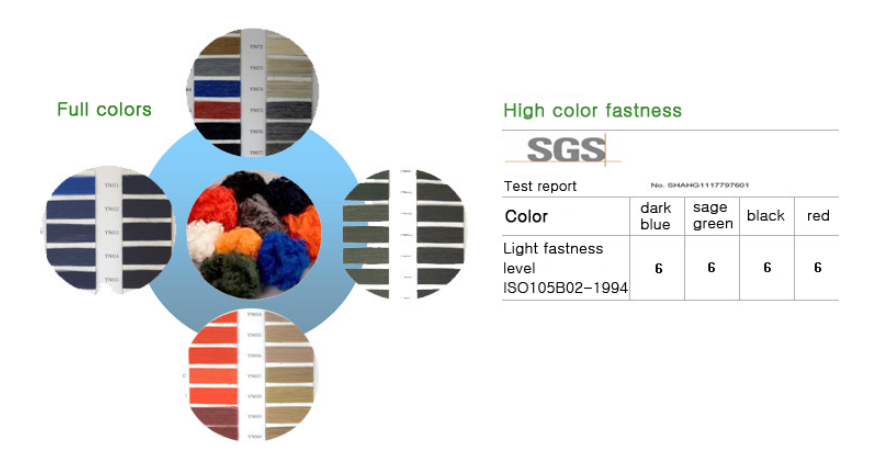

- Perfect combination of protection and fashion

- Perfect combination of protection and fashion

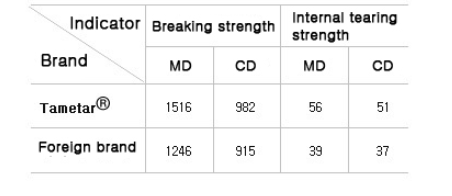

* Excellent mechanical properties

(220g/m2 IIIA dark blue fabric strength comparison)

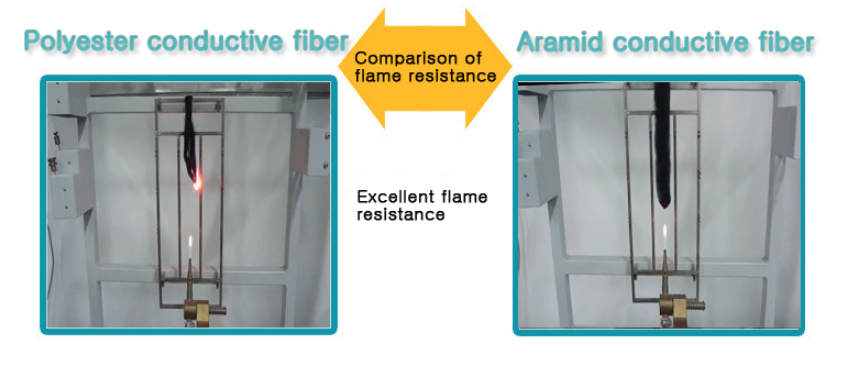

* Excellent flame resistance

With excellent flame resistance, the time of afterflame is almost o second, providing greater protection effect to the users.

- Excellent mechanical properties, wide applications

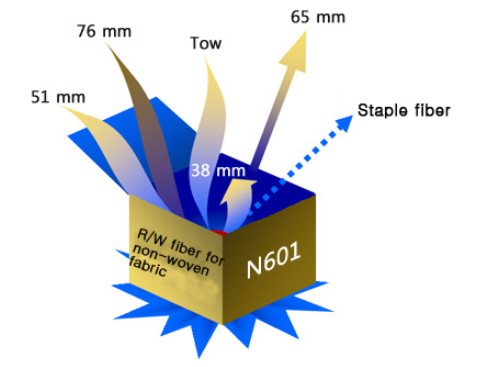

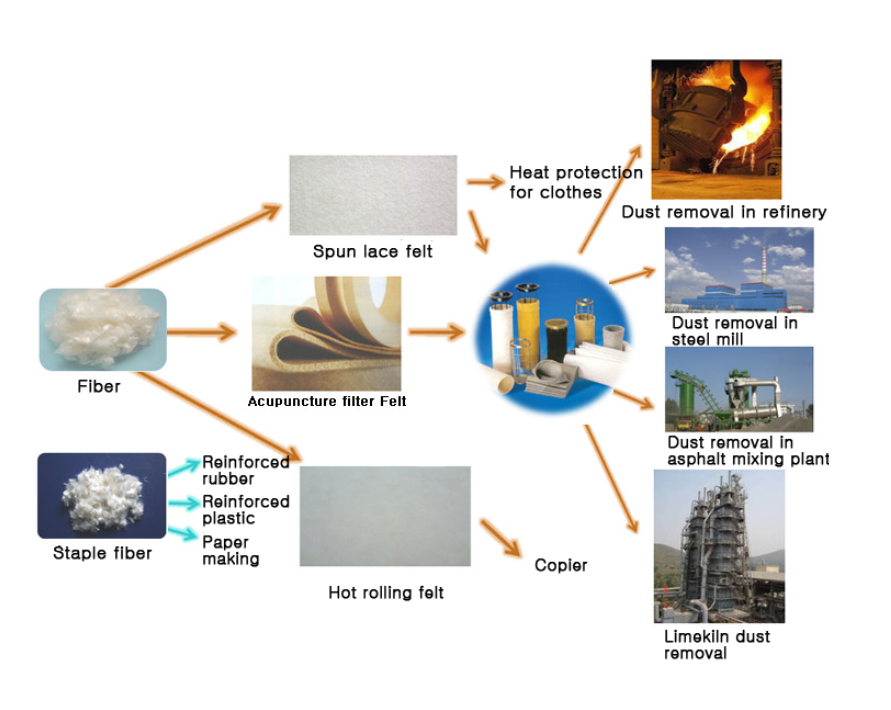

● N601 - R/W fiber for non-woven fabric

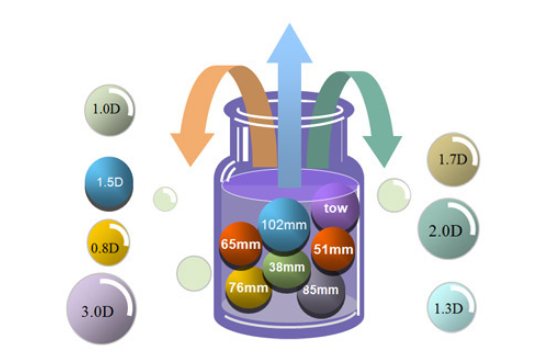

▶ Fiber specifications fully completed

▶ The product available in a range of thicknesses provides a greater value to buyers.

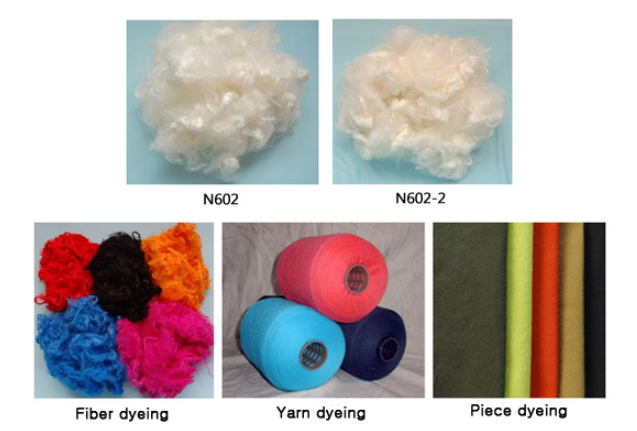

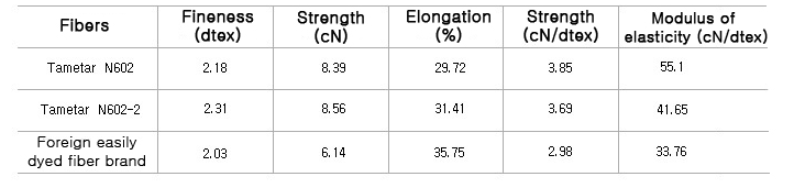

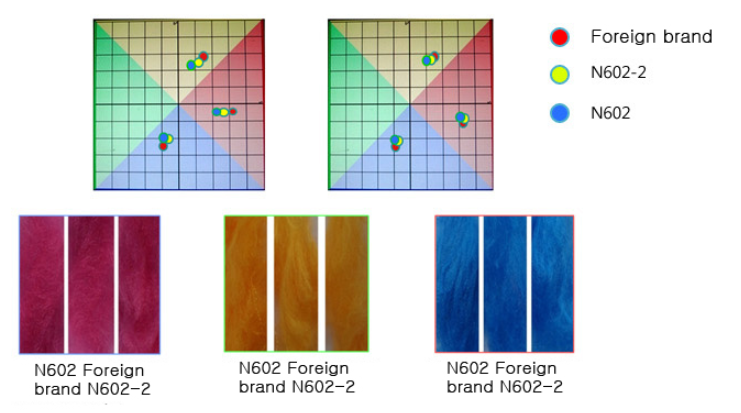

● N602 - Dyeable fiber and N-602-2 easily dyed fiber

▶ This product meets the requirements for mechanical and dyeing properties.

▶ This product meets the requirement for mechanical properties.

This product meets the requirement for dyeing properties.

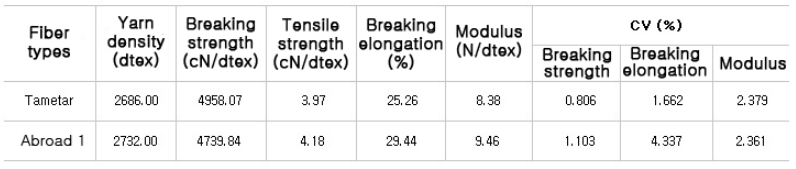

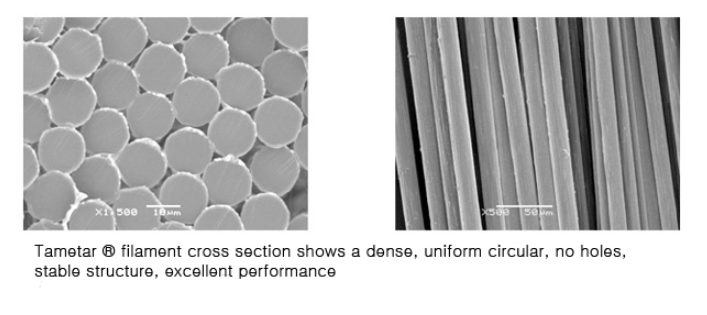

● Filament

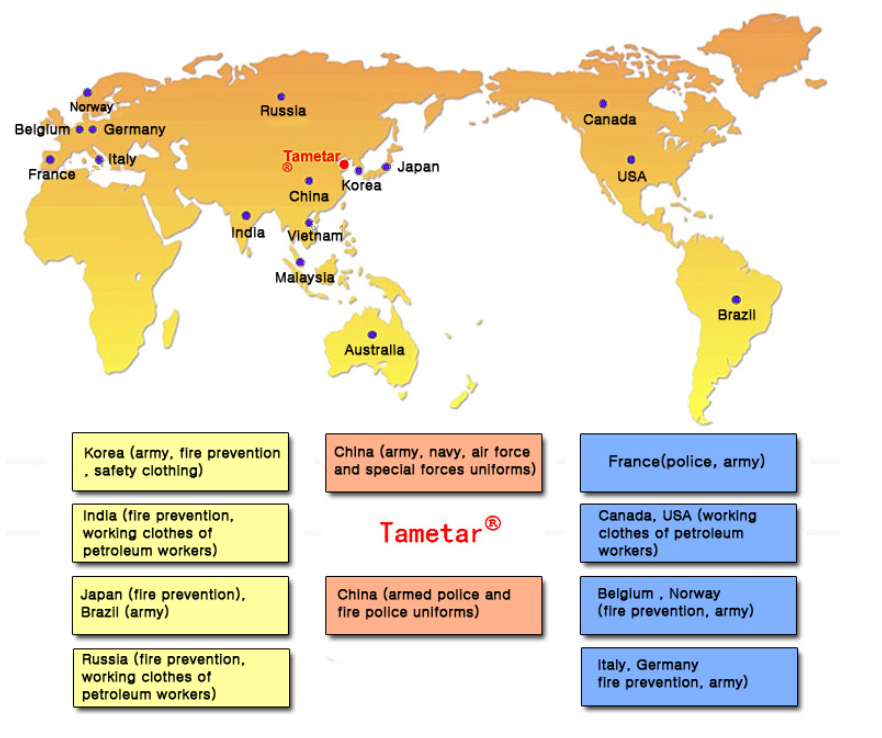

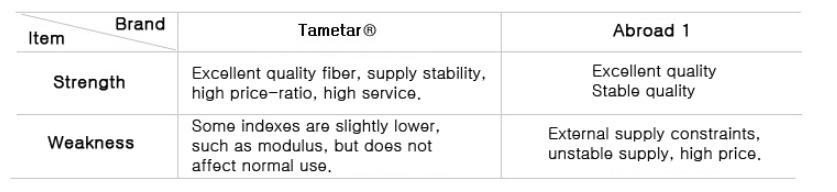

▶ Tametar R/W filament is one of the world's two leading brands

- Products specifications : 200D/100f, 1200D/600f, 1600D/800f Based on 1200D double twisting, the strength is as follows

-Applications: Textile processing, electrical insulation, industrial processing, such as rubber reinforcing, and protective clothing

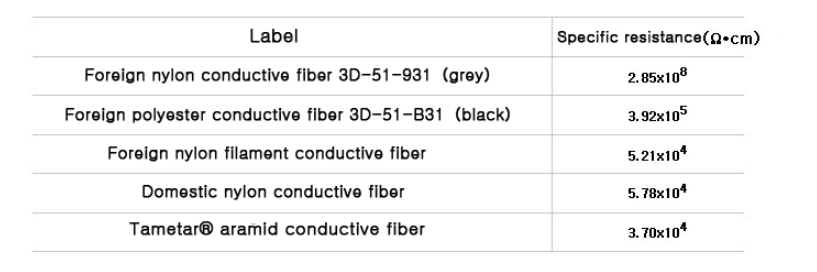

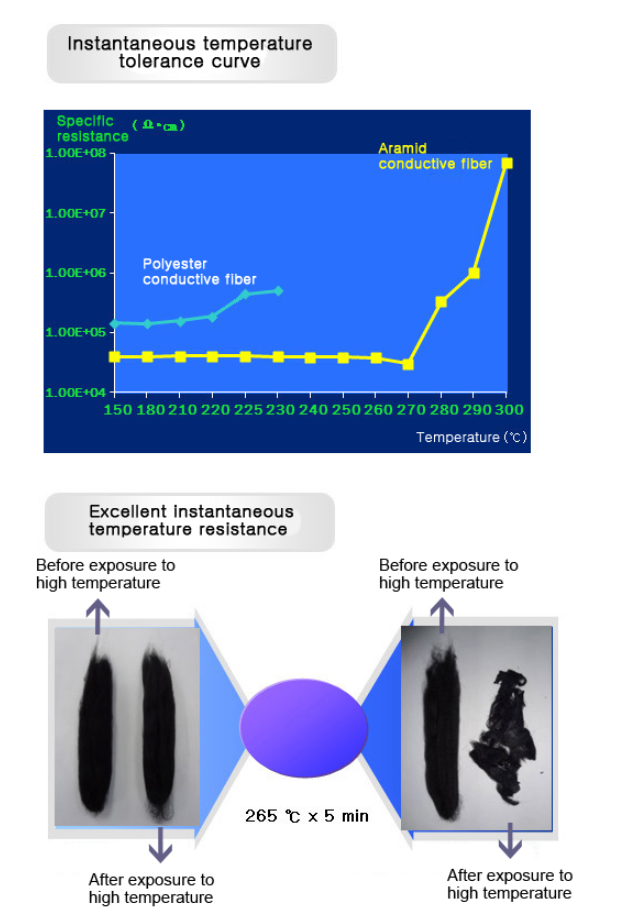

● Conductive fiber

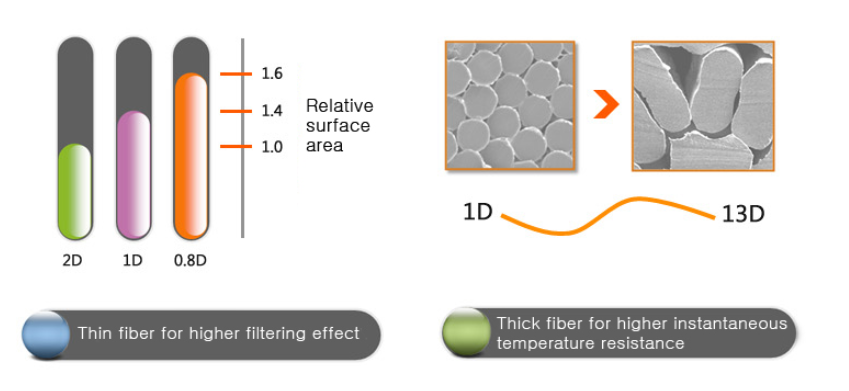

▶ Satisfactory conductivity

▶ Differentiated flame resistance

▶ Excellent instantaneous temperature resistance

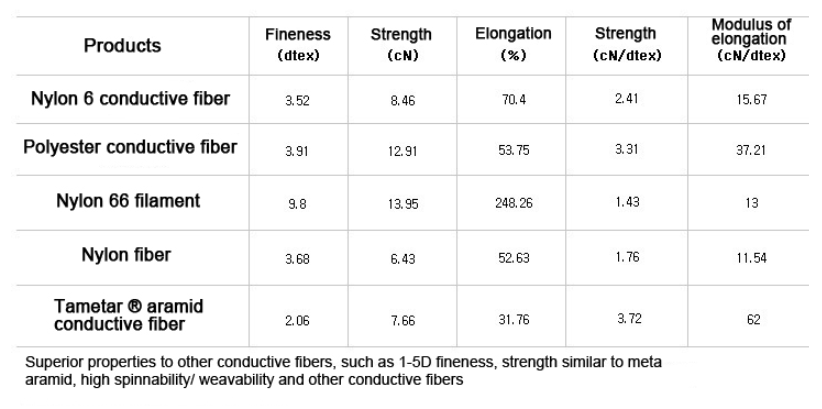

▶ Excellent mechanical properties