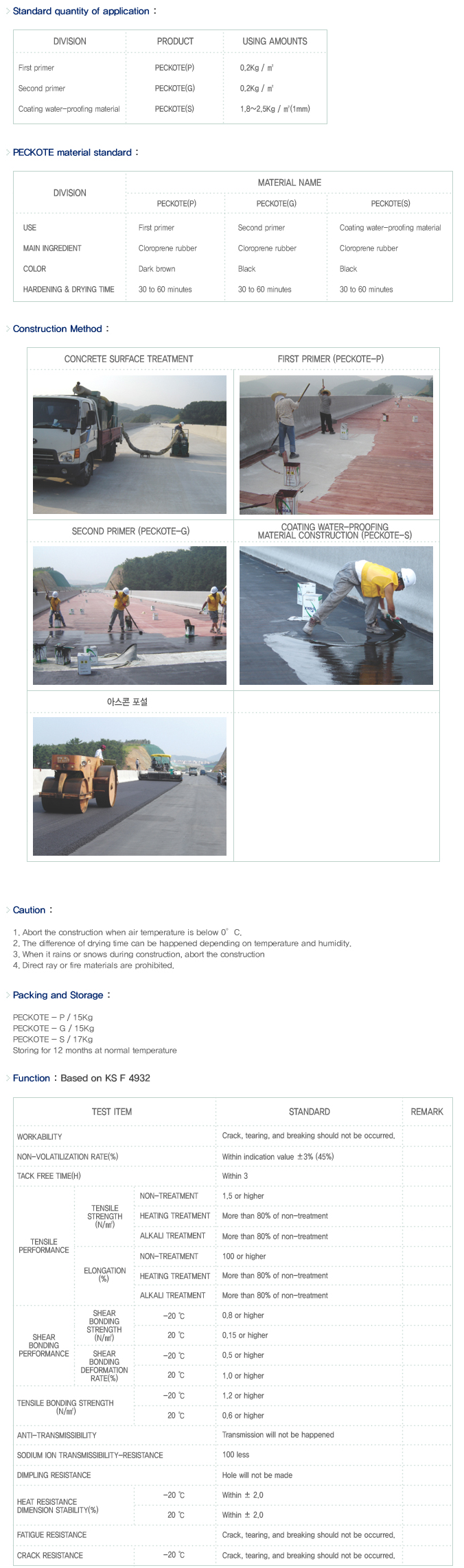

Outline

Film type bridge deck waterproofing can be called the waterproofing method to maintain or increasing durability by protecting structure from the damage due to the freezing corrosion and neutralization of structure, i.e. physical/chemical deterioration phenomenon through the interception of infiltration to the structure of the moisture and salt etc.

On account of the atmospheric change by forming continuous film on the surface of the structure. PECKOTE IS film type waterproofing agent of chloroprene rubber series, and it is the waterproofing agent with superb adhesive force with bridge slab as its thermal resistance, acid resistance, salt resistance, impact resistance, and expansion/contraction property are excellent.

Application

1. Concrete bridge deck waterproofing

2. Overpass deck and railroad bridge deck waterproofing

3. Waterproofing of Concrete box's external wall or various roads

4. Waterproofing of concrete and steel structure which are required of chemicals resistance

Characteristics

1. As chloroprene rubber series primer is used, adhesive force with the slab surface of bridge concrete is excellent.

2. Since it is the chloroprene rubber series, chemicals resistance is superior.

3. Resistance to impact or crack is superb as expansion/contraction property is good.

4. When completely dried, waterproofing layer will not be damaged during the work of various machines (asphalt finisher, dump truck, and roller).

5. As the adhesive force with the asphalt surface layer is excellent and thermal resistance is strong during asphalt pavement, the him waterproofing layer will not be changed even under high temperature,

6. Since the surface of film waterproofing layer displays strong adhesive characteristic during the asphalt pavement, tack coating is not required,

7. In the case of the bridge where the film waterproofing work has been completed, peeling off phenomenon (rising with expansion, pushed back phenomena) of asphalt pavement will not be generated during the passing of various vehicles.