Outline

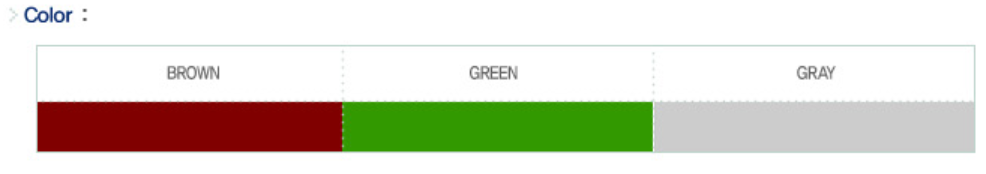

Color Hardener is a floor strengthening agent which has been manufactured with the emery which is a mineral oriented hard aggregate with excellent wear resistance, oxidized steel, alkali resistance inorganic pigment, and special chemicals, and it is the floor finishing agent with remarkable impact resistance and color with good feeling of material

Material property

Emery, oxidized steel, pigment, and special chemicals

Application:

1. Factory floors: Automobile factory, steel mill, machine tool factory, chemical product plant, and power plant

2. Other floors: Parking lot, rooftop, park, filling station, various warehouses, and airstrip

Characteristics

1. Wear resistance (3 times of ordinary mortar)

2. Dust prevention effect (Hard aggregate and special steel powder are used as the main material.)

3. Conductivity (As the oxidized steel which is fine iron particle is used, explosion and fire due to frictional spark will be prevented.)

4. As the construction has been completed before the hardening of concrete, the feeling of unity will be displayed between the concrete bottom and finishing surface

5. Water and oil resistances (Finished surface will not be influenced at all from the water or oil.)

6. As the material is alkali resistance, there will not be any discoloration and the color with good feeling will be displayed

Application method:

1. After pouring the concrete (or mortar), compact flatly to make it horizontal, and when the moisture is withdrawn to the level that the knee can be contacted (approx, 70%) before the complete hardening, spray the color hardener with the amount of 2kg/m2.

2. When the color of material becomes thick due to the absorption of moisture, compact it by pressing with wooden trowel.

3. For the section where the spraying state of the 1st turn is insufficient, compact with iron trowel by adding 1 kg/m2.

4, When the surface becomes dry to the level that footprint will not be appeared, perform the finishing by pressing 23 times while rubbing to one direction with the iron trowel.

5. After completing the finishing work and elapsing 24 hours, either spray water continuously so that the entire surface maintains moisture or cover it with the curing blanket

6. Generally, it is desirable to have the auring period of 1 week, however, in the case of heavy factory with the machinery of big loads, around 3 weeks are recommended.

Cautions

1. Thickness of color hardener shall be applied at least to be more than 3mm.

2. During the application, if there is the possibility that the temperature becomes below 5˚C or to be lower than 50 within 24 hours, the work shall be postponed.

3. During the outdoor application, if there is the concern to have rain within 24 hours, the work shall be postponed.

4, Be careful as there is the concern to have crack generation due to the rapid drying in the summer season.

Packaging:

30 kg/BAG