Outline

Polymer mortar is the polymer S repair mortar of cement group and it is the product to display Superb performance effect on the repair, reinforcement, and durability increase, neutralization prevention of concrete structure etc. through excellent adhesive force to deteriorated structure.

Characteristics

1. Through the non-shrinkage, high strength will be realized in the early stage,

2. With the simple water addition, the workability is excellent,

3, Prevent salt damage and harmful chemical composition.

4, Increase the durability through the reduction of crack generation

b, Freezing fusion prevention effect and wear resistance

6, Excellent waterproofness and chemicals resistance

Application

1, Repair, reinforcing of the vertical, horizontal surfaces of architectural, civil concrete structures

2, Repair the concrete structures of road bridge, tunnel, power plant, and dam etc,

3. Repair, reinforcing of the damaged section of various concrete structures

4, Repairing of water purification plant, waste water treatment plant, drainage outlet, and underground structures of drain pipeline

Application method

1. Adjustment of base surface

Before the construction work, perform thorough cleaning of the base surface so as to eliminate foreign material including dust, oil etc,, and get rid of irregularity and crack state, abnormalities of connection joint section, or other elements obstructing basic performance of the product, Maintain the base surface in wet state during the construction work.

2. Mixing

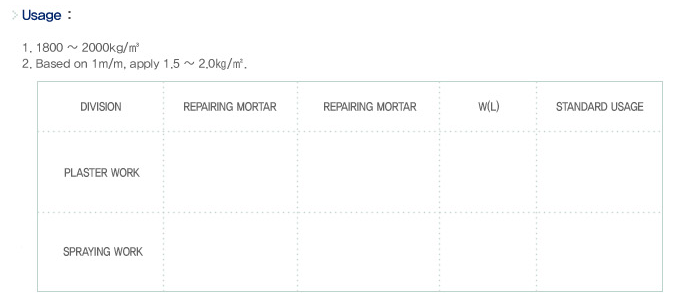

Input the water first with the ratio of powder (repair mortar): water = 25kg: 3.75L ~ 4.25L and perform the thorough mixing for about 34 minutes with low speed electric mixer by adding the repair mortar to be matched with the moisture level of the dough. Quantity of water can be adjusted in accordance with the application method.

3. Coating

First of all, make wet the coated section with sponge, sprayer, and remove the moisture, and then perform the curing with sufficient water spray after spreading the mixed mortar with trowel for plastering or spray coating work.

4, Condition of application work

Avoid direct sunlight, If the temperature is dropped below 5°C or if the rainfall is forecasted, the work can not be performed, and insulation sheet shall be covered so that the work section will not be suffered the freezing damage.

Cautions

1. The product shall be stored under normal temperature in the closed state, and opened material shall be used as soon as possible within 5 hours.

2. If the bottom concrete surface is too dry, there is the concern of reduction of adhesive force or peeling off after elapsing of time due to the absorption of moisture contained in the kneaded waterproofing agent to the bottom concrete inside, therefore, it is necessary to make the bottom concrete in wet condition.

3. If the location of work is exposed to direct sunlight or left to the state of too dry environment, there will be the concern of deteriorating the property of waterproofing layer due to the evaporation of moisture, therefore from the 24 hours after the coating of the waterproofing agent, the curing shall be performed by spraying water for several days for the sake of the suitable hardening.

4, In the case of application work, after mixing and completely agitating with the designated mixing ratio, apply it to the bottom concrete surface by observing the specified coating quantity with brush, large brush, roller, and spray.

Packaging

Powder 25kg/ bag