Marathon

● Unique Inkjet Technology

- As all of Arrayjet's inkjet bio-printers utilise the same core technology, scaling your process is simple. This patented technology is proven to be the fastest and most reliable on the market, delivering speed and precision with the versatility to print any sample type onto a wide variety of substrates.

Compared with traditional microarray spotters, Arrayjet systems are faster and more accurate. Arrayjet microarrayers combine inkjet printheads with the patented JetSpyder™ sample loading device which aspirates multiple samples simultaneously and reduces sample waste. Top quality microarray slides are printed "on-the-fly", at a speed of 640 features per second.

Arrayjet technology delivers numerous customer benefits, including:

▶ Time saving: high speed on-the-fly printing, or large-feature stationary mode printing

▶ Reproducibility: CV values of <5% ensure high quality microarrays with improved positional accuracy and excellent spot morphology

▶ Flexibility: any sample type printed onto any substrate with user-customisable array layouts

▶ Versatility: a scalable range of microarrayers, suitable for low volume R&D, large scale production and everything in-between

▶ Sample conservation: the unique sample loading device, reduces dead volume and minimises sample waste

● Arrayjet printhead; fast, robust and flexible printing

- Arrayjet microarrayers are fitted with Xaar XJ126 piezoelectric printheads. This is an industrially proven, multi-nozzle, shared-wall printhead with 126 linearly-arranged nozzles that enable Arrayjet microarrayers to handle up to 32 samples simultaneously.

The innovative printhead dispenses samples onto your chosen substrate, printing at a rate of approximately 475 features per second: this translates into the capacity for printing an entire 384-well plate onto 100 slides in under 25 minutes.

▶ Flexibility: on-the-fly printing enables printing of high quality microarrays on a wide range of substances, not only glass slides

▶ Sample preservation: the piezoelectric printhead protects samples so they are neither heated nor charged during printing

▶ Surface protection: non-contact printing prevents surface damage

▶ Flexible printing and exact spot size control: variable deposition volumes suitable for all applications, from 100pL to 10nL

▶ Accuracy and speed: the printhead travels across the substrate at 20 cm.s-1. Multiple passes can be made before refills are required, thereby significantly reducing the lengthy print times associated with pin-spotting

● JetSpyder™: more flexibility, less waste

- The JetSpyder™ is Arrayjet's patented sample loading device used in all Arrayjet microarrayers. Designed and manufactured at Arrayjet it enables the printhead to dispense multiple samples simultaneously, with minimal sample waste.

▶ Print different samples, simultaneously: the unique JetSpyder™ design can aspirate 32 or 12 samples at one time, enabling up to 32 samples to be printed in a single pass of the printhead

▶ Efficient and economical: the JetSpyder™ transfers minimal sample volumes to the printhead, ensuring the usable volume of precious samples is maximised

▶ Sample protection: manufactured from non-hazardous materials and automatically cleaned before a print run, the JetSpyder™ minimises the risk of sample contamination

● Iris™ Optical QC

-Arrayjet has developed a dual-camera optical QC system, available now as an upgrade on the Marathon series of instruments.

The Iris™ system consists of twin cameras mounted on either side of the print head. Each camera captures images within 300 ms of sample deposition, moving across the printed slides in conjunction with the print head.

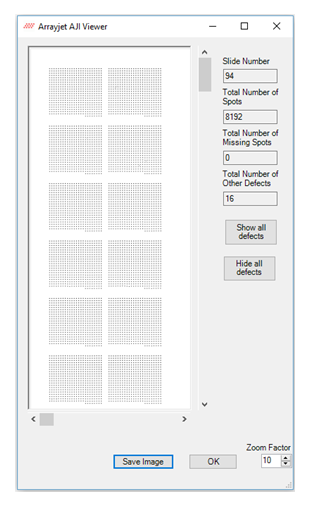

Images are processed in real time, detecting the presence of missing spots, artefacts, merged or misaligned features. Upon completion of the print run, print quality for each slide of the entire batch is reported. These images can be accessed immediately and also saved for future reference and traceability.

A final report will inform the user of the percentage of imperfections on a slide-by-slide basis.

● Customisable thresholds

- Users have the option to select a threshold for quality of the printing. Percentage of missing spots and/or other defects can be chosen from the setup window before the printing starts.

Positional accuracy and spot diameter variations can also be reported, if requested.

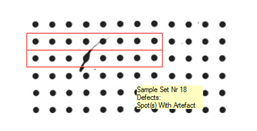

● Imaging and reporting of defects

- The print quality report of each individual slide includes images of the printed spots captured in real time. The Command Centre software analyses each image and generates qualitative and quantitative data for any detected defects.

A global report for the quality of the whole manufacturing run is generated automatically and can be saved to ensure complete traceability of manufacturing runs.

The software highlights to the user the defects found and categorises the defect type such as missing spot, artefact, merging spots, satellites present or misalignment.

Integration of the Iris™ with Arrayjet Marathon instruments gives access to a reliable QC system for reliable high-throughput batch manufacturing.

● High-throughput: Ultra Marathon Series

- With the capability of producing the largest batch sizes on the market, the Ultra Marathon I and II are ideally-suited to high-throughput array manufacture, with optional modularity allowing system configuration to match desired output.

With unparalleled speed, both the Ultra Marathon I and II meet the production requirements of most bioarray formats, including slides (1000 per batch), microplates (200 per batch) and biosensors.

Multi-functional capabilities and tight environmental control make the Ultra Marathon range suitable for varied high-throughput applications, including but not limited to:

▶ Antigen discovery

▶ Biomarker screening

▶ Antibody validation

▶ Epitope mapping

▶ Small molecule library screening

▶ Hybridoma screening

▶ Gene expression profiling

▶ SNP analysis

▶ Host-pathogen interaction profiling

▶ Comprehensive microarray polymer profiling (CoMPP)

● Technical Specifications

Technical information | Marathon Classic | Marathon Argus | Super Marathon | Ultra Marathon I & II |

|---|---|---|---|---|

Input Capacity: | 6 plates | 48 plates | Ultra Marathon I: 6 plates Ultra Marathon II: 48 plates | |

Output Capacity: |

Up to 100 slides

| Up to 1,000 slides | ||

Print Speed | 640 features per second | |||

Optical Camera QC | No | Yes | ||

Sample Handling: | 12 sample Reduced Aspiration JetSpyder – as standard 12 sample High Capacity – optional except Classic 32 sample Ultra-low Aspiration Capacity JetSpyder – optional except Classic | |||

Printhead: | Xaar XJ126 piezoelectric printhead, 126 nozzles 100 pL to 10 nL (100 pL increments) 90 - 500 µm +/- 10 µm | |||

Dispensing Volume: | ||||

Feature Size: | ||||

Print Accuracy: | ||||

Weight: | 330 kg / 725 lbs | 340 kg / 750 Lbs | 420 kg / 925 lbs | |

Height: | 1.70 m 1.56 m 0.89 m 220 V, 50/60 Hz or 110 V, 50/60 Hz | |||

Width: | ||||

Depth: | ||||

Power: | ||||