Back Grind Tape

- After finishing patterning on the wafer, we have to grind the backside of the wafer to make it suitable thickness. In this application, PSA tape is used to protect the patterned circuit on the wafer.

After the wafer was finished by polishing and other process, the die on the wafer has to be sawing in each chip. In this application, PSA tape has to be used to prevent the chip-fly and help pick up easily. There are 2kinds of PSA tapes such as non-uv tape, uv curable tape.

● Feature

- As base film is polyolefin, it is free from deficiencies caused by PVC film such as plasticizer migration, bad odor, and so on.

- It has optimum adhesive strength enough to hold chip during wafer sawing process.

- No contamination on the backside of chip due to deionized water or silicon dust

- Smooth pick-up can be possible after a period of long storage.

- Very excellent lamination with wafer and easy delamination from wafer during backside grinding process.

- Completely free from fish-eye, gel, foreign material and so on which may cause damage to wafer.

- As it is free from silicon , detergent and wax compositions in its adhesive, de-lamination of epoxy never occur during package process of chip.

● Specification

| ||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||

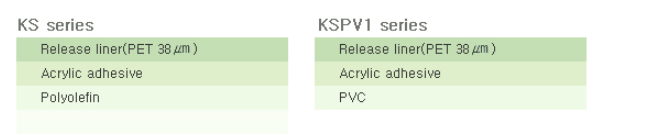

● Construction

● Application

- Dicing of water

- Protection of semiconductor circuits during the process of wafer backside grinding