Dicing Tape

- Dicing Tape is applied to prevent dust scattering, when wafer as semi-conduct background is sawed for discrete device. There are two kinds of general decompression type and ultraviolet curable type.

As chip size of semiconduct is larger and thickness becomes thinner with high density integration, dicing tape typed UV curable because we must prevent dust scattering of chips by powerful adhesive strength when process in dicing before UV Irradiation and we must prevent damage such as micro crack, etc to chips incurred by the reason why adhesive strength can be weak and easily be peeled off after UV irradiation when process in pick-up.

● Specification

Item | KS-HC170 | KS-HC220 | KS-TC145 | KS-TC210 | ||||||

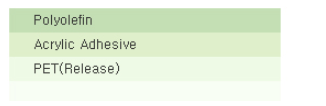

Structure & | Base Film | Polyolefin | Polyolefin | PET | PET | |||||

Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | ||||||

Protective Film | PET | PET | PET | PET | ||||||

Thickness | Total | B/F | 170 | 150 | 220 | 200 | 145 | 125 | 210 | 190 |

Adh | 20 | 20 | 20 | 20 | ||||||

Adhesion | Before UV | 1100 | 1100 | 2500 | 2500 | |||||

After UV | Less than 35 | Less than 35 | Less than 35 | Less than 35 | ||||||

Application | Non-UV | UV | COB & COF | COB & COF | ||||||

● Construction