Specific gravity | : | 1.18 ~ 1.23 (15/4℃) |

Viscosity | : | Powdered graphite products are difficult to measure the precise viscosity. |

Freezing point | : | -9℃ or -10℃ |

| : | (-20℃ or -4°F for frigid zone) |

Carrier | : | water |

Appearance | : | black |

pH | : | 11.0 ~ 11.5 |

※ The above number can be changed according to product development and other circumstances.

▶ FEATURES

- Excellent lubricity

- Good release properties

- Extends die life

- Non-polluting

- Die temperature control by the dilution ratio adjustment

- Non-flammable

- Non-corrosive

- Smokeless ; no fumes or ammonia gases

▶ APPLICATION

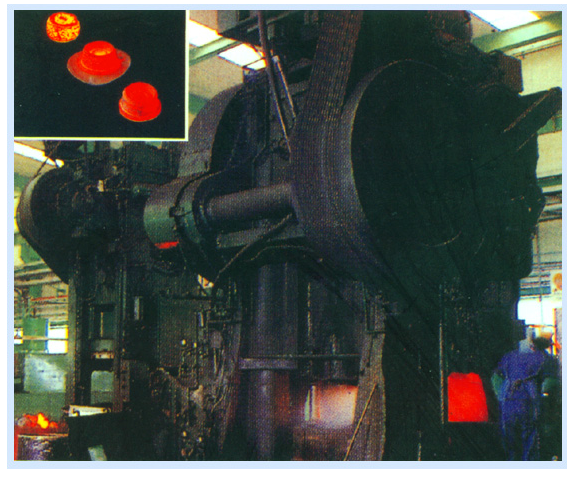

- Demoulding lubricant for hot forging of steel (especially more difficult work, precision forging), stainless steel, nonferrous metal, and aluminum extrusions

▶ USAGE

- Dilution : For initial trials, one part of BW-100 to ten parts of water by volume is suggested. We recommend to determine dilution ratio during operation according to the condition of die surface and the working condition.

- Application : Spray (Manual or automatic)

▶ STORAGE

- Store BW-100 in a cool place

- Be cautious not to freeze

▶ SHELF LIFE

- 1 Years under the original seal

(※ The term of validity is not absolutely number, which can be extended)

● BW-100 (WARM FORGING LUBRICANT)

- It has the similar ingredient as hot forging type BW-100 and has a strong application effect.

▶ Application

- Warm forging lubricant especially for synchronized shafting and gear forging

▶ Usage

- The material should be kept between 100℃±10 during deeping or spray deeping. It should be diluted with water with the dilution ratio of "water:BW-100(warm forging)=5:1." For spray, it should be diluted with water with the dilution ratio of "water:BW-100(warm forging)=8:1."

※ This products may happen to have some sedimentation,

but it can be easily diluted with water and use with no problem