Urea molding material

- Urea molding resins are used in adhesives, finishes, MDF, and molded objects. These resin's attributes include high tensile strength, flexural modulus and heat distortion temperature, low water absorption mould, high surface hardness, elongation at break and volume resistance.

● Urea Molding Compound

-Urea Molding Compound is one kind of thermosetting materials, Which is made of Urea Formaldehyde Resin and the filling materials of (Alpha) -fiber element and filling the organic or inorganic materials or other additives. This has the characteristics of bright color, good appearance, and no odor with good mechanical property and good insulation resistance, it is widely used in buttons and pins, imitation pearls, various kinds of commercial boxes and covers.

* Physical and Chemical Properties

Test Item | Unit | Properties (conditions) | Remark | |

Physical | Specific Gravity | g/cm3 | 1.4~1.5 | KSM |

Contraction | % | 0.6~0.8 | ||

Absorption | % | 0.05~0.2 | ||

Heating transformation | ℃ | 110℃ min (1hr) | ||

Mechanical | Impact Strength | Kgf.cm/cm2 | 2.5~3.5 | |

Bending strength | Kgf/mm2 | 10 min | ||

Tensile Strength | Kgf/mm2 | 6~8 | ||

Electrical | Insulation Resistance | Ω | 109 min | |

Withstanding Voltage | Kv/mm | 10 min | ||

Molding | Mold Temperature | ℃ | 135-160℃ | |

Mold pressure | Kg/cm2 | 150~250 | ||

Curing time | Thickness 1.5mm | 30-50sec | ||

Thickness 3.0mm | 50-80sec | |||

Thickness 5.0mm | 70-100sec | |||

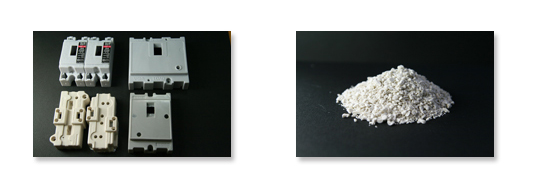

● Urea Injection Molding Compound

- Their high mechanical strength, heat and fire resistance, and good electrical arc and tracking resistance make them an ideal plastic for numerous industrial and household applications. It is commonly used when producing spares of electrical appliance spares: switch, fittings, sockets, cases and Machinery spares: knob, handle, spinning machine components, instrument shell, clock shells.