Photo chromic pigment

- Photo chromic pigment is suitable for several application such as extrusion, injection, PP, PE.

- PVC, K-resin, epoxy, printing, labeling etc.

- Photo chromic pigment can be processing to masterbatch in order to keep uniform colors.

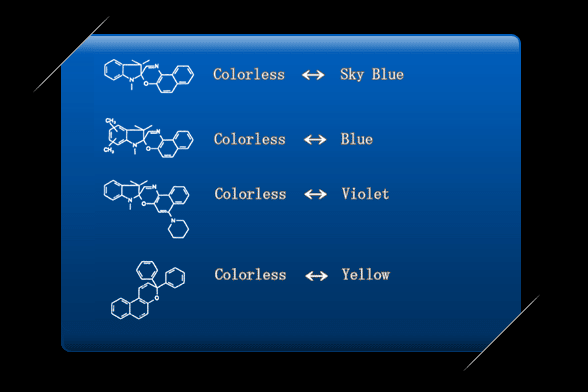

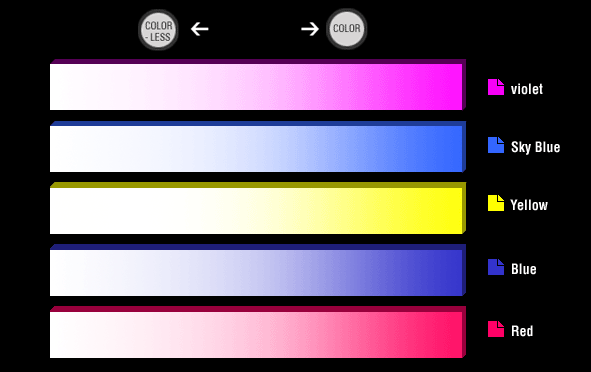

● colors

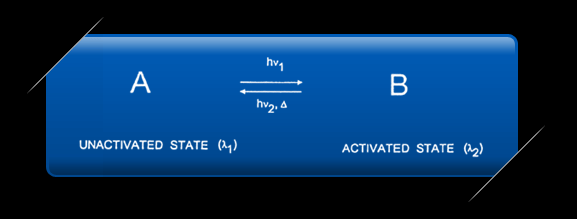

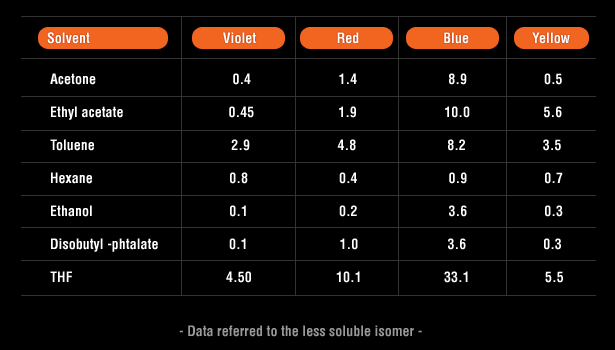

• The characteristics of photo chromic pigment

- Photo chromic is not observed on products in the crystalline state and its color changes when smelted in plastic or solvent.

- Photo chromic Blue Violet Yellow and Red colors can be degraded by acids or strong oxidizing agents (e.g. peroxides). Compatibility with this kind of chemicals must be tested in advance.

- The UV absorber can hinder the photo chromic effect

- The photo chromic response depends on the characteristics of the host medium (polarity. T g etc.), and technique used in preparation of the specimen (melt processing, casting, thermal transfer etc.)

- Photo chromic pigment can be mixed together to obtain the desired color in the activated state. It can be also mixed with ordinary pigments.

● Application for Epoxy