What is the "Gravure Printing?"

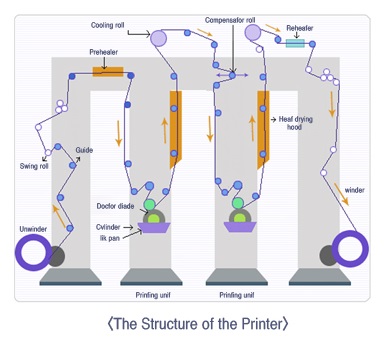

In this printing method, first you have to fill ink in the hollow area of the plate opposite to the letterpress. Then, using a metal apparatus called "Doctor Blade(scraperP)" you have to rake out the left, unnecessary ink on the bulging area. Next, loading the printing pressure on the ink existing in the same hollow area, you have to transfer the ink on the hollow area to printed materials such as paper, film, fiber, etc.

This printing method is usually used to print bills and stamps. It is largely divided into two printing types: "Engraving Printing and "Gravure Printing." In the "Engraving Printing," a metal plate is engraved for printing. In the "Gravure Printing," a metal roll to which photographing techniques have been applied is plated, and is used to print books, copy pictures, do printing using plastic film, etc. In engraving printing also, the "Gravure Printing" is representatively used. It is called "Photogravure Printing."

In "Letterpress Printing or "Lithographic Printing," if you load ink thickly to express light and shade, the ink spreads and then, the directional line becomes unclear. On the contrary, in the "Engraving Printing, the process of pressing ink is not applied, so that you may load ink thickly without losing the clearness of the directional line.

If you examine the matter printed in the "Gravure Printing" method with a magnifying glass, you may find a number of dots. These dots form a number of cells and an image in the form of a thinly-cut small mass. In other words, the plate of gravure is composed of small cells. If ink is filled in the same plate, the scraper will rake out it, and the required ink will be left. In addition, the "Gravure Ink” is adjustable in expressing the shade and light of the direction line depending on plate-making methods, plate levels in depth, and dot sizes.

Features of "Gravure Printing"

- Available for printed on various printing substrates due to the use of a metal engraving system and low-viscosity type ink

- Long life span of a plate and high-speed printability

- Printable on thin paper, film, etc.

- Endless printing

- Excellent representation in expressing color tone.

- Requires an explosion-proof drying equipment and a ventilation system due to the use of solvent-typed ink

- Much time in photolithography and printing plate work, and more expenses for plate-making machinery than other printing methods.

- Even-surfaced film as a printing substrate need for good printing effects

- Low adhesive strength if printing is carried out on any heat-sealing area.

Features of Gravure Ink

The printing performance using "Gravure Ink” depends on how to apply the characteristics of the cylinder. In other words, if ink coating is successfully finished applying 5-7μ depth to the maximum length or 40μ depth to the minimum one, it is possible to get a good printed matter. Thus, to be good ink, it has to be maintained at 50% 55% of high solid and at low viscosity of 15-40 sec on a basis of cup #4.

The Formulation of Gravure Ink

1. Coloring Agent

A good coloring agent requires many function such as tinting strength, hiding power, absorption, specific gravity, particle level, heat-resisting property, weather resistance, solvent resistance, chemical resistance, sanitation, electrical insulation, etc. The coloring agent is divided depending on a number of factors such as its chemical structure, crystal form, particle level-distribution, surface conditions, reflective index, etc. The coloring agent is mainly classified into a pigment and a color. The pigment is again divided into a mineral pigment and an organic pigment. A body pigment is sometimes used to adjust all the physical properties. A color needs to be well solved in a solvent in the state of a molecular, and is excellent in coloring. It is also excellent in transparency and iink fluidity, but is gradually replaced by a pigment due to some problems with its bleeding, migration, light fastness, chemical resistance, and food hygiene.

2. Vehicle

A vehicle is a general term for a dispersion medium used for a coloring agent, a component of ink. It affects ink liquidity and drying property, printability, the adhesive property to printing materials, and a processability of printing film depending on uses.

The vehicle is mainly divided into a binder and a solvent. The binder affects deciding the kind of a resin in printing, which is also decided depending on the kind of film, and the kind of a resin affects deciding the kind of a solvent. The resin is divided into a natural resin, a synthetic resin, and a cellulose-based resin. If the resin is ind

A solvent is a general term for a list of organic solvents. The organic solvent plays a good role in solving a resin in ink, and it provides good liquidity and viscosity to ink, and helps a pigment disperse in humidity as well as preserves ink. It also maintains and improves printability, strength of printed film, and adhesive strength.

The solvent should be stable on a printer, especially its plate, and its dryness after transferred adhesion to printed materials needs to be adjusted in speed. In addition, the solvent must not be left on the printed film after dried. Thus, it is necessary to select a dryable solvent that suits printing speed, printer performance, and weather conditions.

For gravure ink, a solvent is rarely used in its own element, but instead, a mixed solvent is used in consideration of solvency, printability, drying speed, etc. It is required to use an exclusive solvent that suits its ink type. If an inappropriate solvent is used, ink gelation, separation, poor color development, etc, may occur.

3. A Supplemental Agent and an Additive Agent

These agents are added to the gravure ink which uses a coloring agent and a resin solvent as its main raw materials. The agent used to preserve and improve those functions is called "a supplementary agent. It has such a function as ink preservation, stability, printability, a physical property of printed film, and improvement of processing characteristics, etc..