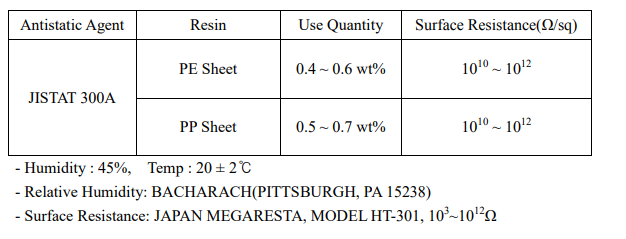

JISTAT 300A - ANTISTATIC AGENT FOR PE AND PP

- JISTAT 300A is an internal antistatic agent for use in PE and PP. PE and PP is so hydrophobic and it is very difficult to adsorb the moisture from the ambient air that it is easy to take the static charges. This static charges are the reason of the electric shock and surface spoil when the plastic is used for the parts of electronics or bottles for packing or sheet and film. JISTAT 300A is an efficient antistatic agent for use in PE and PP.

● PRODUCT FEATURES

- Excellent antistatic and dissipative activity

- Excellent durability and compatibility

- Excellent light stability and heat resistance

● TYPICAL PROPERTIES

.png)

● APPLICATION

- Effective on PE and PP

● Application Example

● HANDLING AND STORAGE

- The self life of this agent is minimum one year in normal indoor.

- Do not use near fire or flame.

- Store in well-ventilated place.

● PACKAGE

- NET 20 Kg in box

● APPLICATIONS of JISTAT 300A

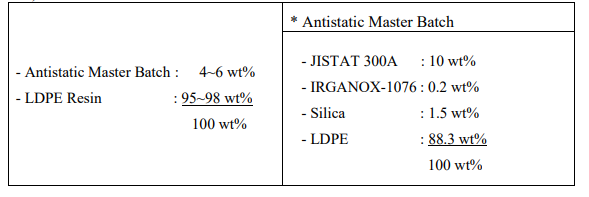

1. Formulation

1) LDPE-Film Formulation

* Master Batch technics ars more efficient way than directly mixing antistatic agent with LDPE resin for dispersing.

* Above formulations are for antistatic function, if you want to add another function on plastic, you can use other additives with antistatic agent.

⇒ UV Stabilizer, HALS, Colorant, Filler etc

* If antistatic agents are used over 0.3%, wet-blocking can be occurred between film.

* If antistatic agents are used too low, poor slip can be occurred between film and the film takes static electricity.

2. Remarks

1) Guarantee of Product Quality : 1 Year after production

2) If possible, don't raise the temperature to 250℃ during extrusion or injection processes.

3) FDA regulation for food packing materials : Max 0.5%

4) The more porous TiO2, CaCO3, Zeolite, Silca is used, the more antistatic agent (10~20%) must be used.

5) Trial application tests are recommended, though this applications are well-known recipes.