Plant Growth Chambers

● Performance

▶ General control system

- 5℃to 50℃(lamp off) / 10℃to 50℃. (lamp on)

- Max. to 35,000Lux for GC-1000.

- Max. to 20,000Lux for GC-300 Models.

- 40 to 80% RH for GC-300TLH. (at 20 to 35℃)

- 50 to 90% RH for GC-1000TLH. (at 20 to 35℃)

- Max. 5,000ppm CO2 on/off system. (optional)

- Microprocessor PID control / Temperature calibration / Automatic tuning.

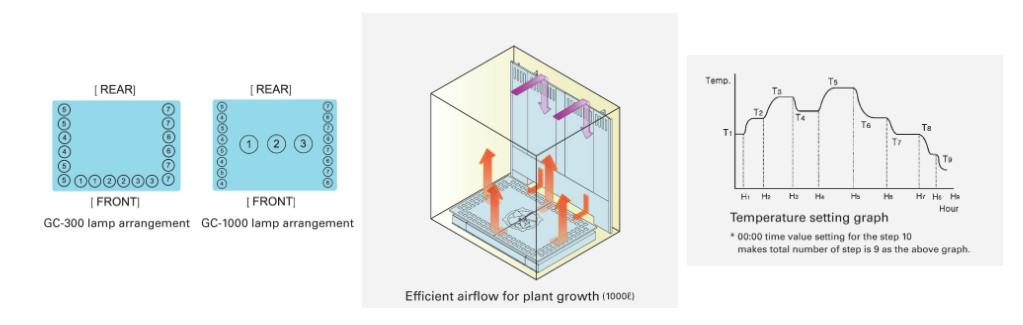

- 10 step programmable temperature, humidity, and illumination profiles and repeatable steps of up to 999 cycles.

▶ Illuminance control system

- Uniformed luminescence distribution.

- Broad distribution of side lamps for hastening the growth of plants.

- High intensity illumination of upper lamp for light efficient and low thermal load. (for GC-1000TLH/1000TL)

- Unique construction for minimization of heat increase from surrounding lamps.

→ Tempered glass door blocks heated air from lamps.

→ Designed to exhaust heated air through upper vent holes. (for GC-1000TLH)

- Stable and long lasting lighting through introduction of high frequency electronic ballast lamps.

● Convenience

▶ Ergonomically designed door construction.

- Inner glass door with silicone and external door with magnetic sealing for dual airtight packing.

- Well designed providing a smooth open for minimization of damage to plants.

▶ Wide inner tempered glass door for clear observation of plant growth without affecting inner chamber’s environment.

▶ Tall plants can be grown inside of the chamber with adjustment of shelve level.

▶ Maintenance of water supply are easily performed with a front water tank. (GC-1000TLH)

- Water level check indicated by water level bar in the tank.

▶ Water supply during operation is also available for long term test purposes.

▶ Adjustable water tank position. (for GC-300TLH)

▶ Detachable condenser air-filter for easy maintenance of refrigerating efficiency.

- Maintenance of air filter no longer cumbersome with our detachable condenser air filter.

▶ Casters for easy mobility during installation or relocation.

▶ Eco-friendly CFC-free refrigerant use.

● Safety

▶ Automatic shut off after overheat alarm.

▶ Low and empty water level alarm.

▶ Power supply leakage breaker.

▶ Over current protection,

▶ Open door alarm.

▶ Lamps setting

* Control illumination values with the below lamp setting arrangements.

● specifications

Model | GC-300TL | GC-300TLH | GC-1000TLH | ||||

|---|---|---|---|---|---|---|---|

Chamber volume (L / cu ft) | 300 / 10.6 | 1000 / 35.3 | |||||

Control system | Microprocessor PID controller | ||||||

Temperature | Range (℃ / ℉) | 5 to 50 / 41 to 122 - Lamp off | |||||

10 to 50 / 50 to 122 - Lamp on | |||||||

20 to 50 / 68 to 122 - with humidity | |||||||

Fluctuation (±℃ / ℉) at 25℃ | 0.1 / 0.18 - without humidity | ||||||

Variation (±℃ / ℉) at 25℃ | 0.8 / 1.43 - without humidity | ||||||

Illumination | Range (Lux) | 0 to 20,000 | 0 to 35,000 | ||||

Control (steps) | 10 | 11 | |||||

Lamp | Fl lamp (32W×18ea) | FL lamp (32W×16ea) | |||||

Metal lamp (400W×3ea) | |||||||

Humidity | Range (% RH) | - | 40 to 80 at 20 to 35℃ | 50 to 90 at 20 to 35℃ | |||

70 to 90 at 36 to 50℃ | 60 to 90 at 36 to 50℃ | ||||||

Fluctuation (±RH) at 60% RH | - | 3 | |||||

Co2(optional) | Range (ppm) | Max. 5,000 | |||||

Sensor | NDIR CO2 sensor | ||||||

Refrigerant (HP) | 1/2 | 3/4 | |||||

Temp. heater power (W) | 750×2ea | 1,500×2ea | |||||

Humid. heater power (W) | - | 1300 | 1500 | ||||

Dimension (W×D×H) | Interior (mm / inch) | 510×540×1100 / 20×21.3×43.3 | 1200×800×1080 / 47.2×31.5×42.5 | ||||

Exterior (mm / inch) | 700×805×1900 / 27.6×30.1×74.8 | 1410×1070×2150 / 55.5×42.1×84.7 | |||||

Net weight (kg / lbs) | 250 / 551.2 | 550 / 1212.5 | |||||

Electrical requirements (230V) | 60Hz / 12.5A | 50Hz / 12.5A | 60Hz / 16A | 50Hz / 16A | 60Hz / 30A | 50Hz / 30A | |

Cat. No. | AAHA1012K | AAHA1012K | AAHA1022K | AAHA1022K | AAHA1031K | AAHA1032K | |