Dispersant of Boron Carbide for Lapping

- Sapphire is a crystal boules of aluminum oxide (Al2O3) formed at the 2050℃. Because of the remarkable hardness of sapphires, 9 Mohs scale (and of aluminum oxide in general), sapphire has infrared optical characteristics, superior heat conductivity, stability between low and high temperature similar metal in ceramic material.

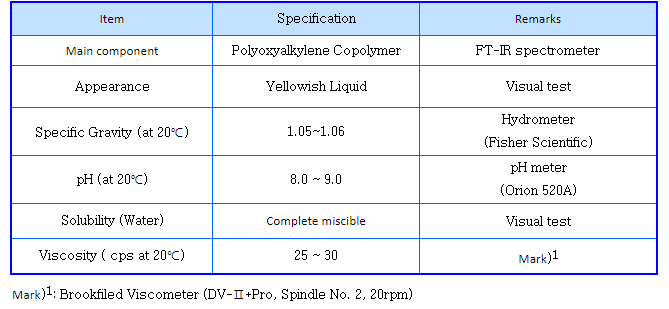

● Product Name: BCD-700

- Sapphires are used in semiconductor circuits and parts applications, including infrared optical components, laser parts applications, and very thin electronic wafers, which are used as the insulating substrates of very special –purpose solid-state electronics (most of which are integrated circuits). Specially TV, LED light are growing industry field.

For the sapphire wafer process, before DMP (Diamond Slurry) and CMP (Colloidal silica) polishing process next steps as following; First, Lapping process is generally using the Boron carbide (B4C) of 240mesh as a polishing material. Generally mixing ratio of weight are distilled water 10, Boron carbide (B4C) powder 3.5 and dispersion agent 1. Specially, surface plate material is Cast Iron that is using on the lapping process is easy to create rust. It is required to have anti corrosion ability. BCD-700 is wet dispersant for stable disperse Boron carbide (B4C) particle. It has superior lubricities and anti-corrosive.

▶ Physical characteristics

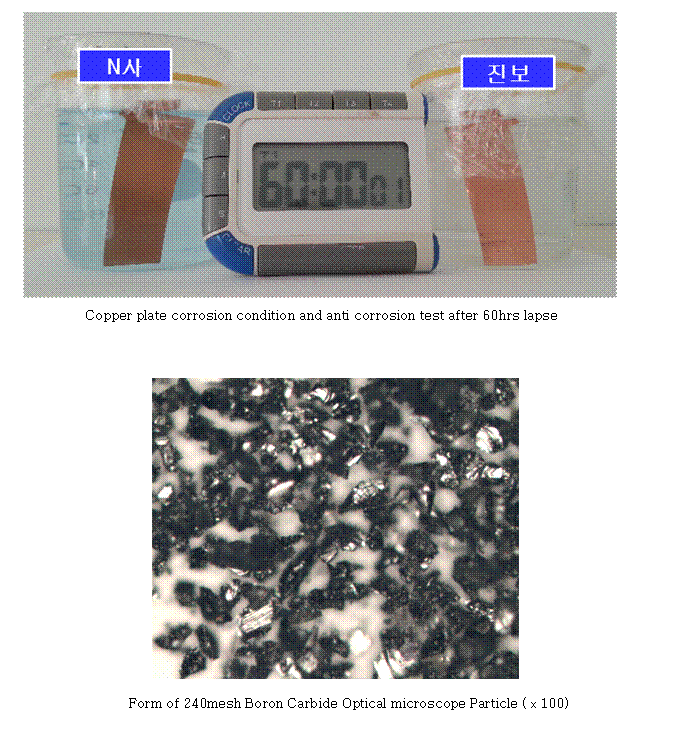

▶ Anti corrosion test

It is mixed with 10:1 ratio of distilled water and dispersion agent in the 100ml Beaker, dipping pure (99.999) copper plate at each beaker, cover the top of Beaker with clean wrap, store dry oven of 40℃, and compared corrosion condition after 60hrs lapse.