Adhesive for Wafer Polishing

- Sapphire is a crystal boules of aluminum oxide (Al2O3) formed at the 2050℃. Because of the remarkable hardness of sapphires, 9 Mohs scale (and of aluminum oxide in general), sapphire has infrared optical characteristics, superior heat conductivity, stability between low and high temperature similar metal in ceramic material.

● Product Name: : SPA-140 and SPA-140H

- Sapphires are used in semiconductor circuits and parts applications, including infrared optical components, laser parts applications, and very thin electronic wafers, which are used as the insulating substrates of very special –purpose solid-state electronics (most of which are integrated circuits). Specially TV, LED light are growing industry field.

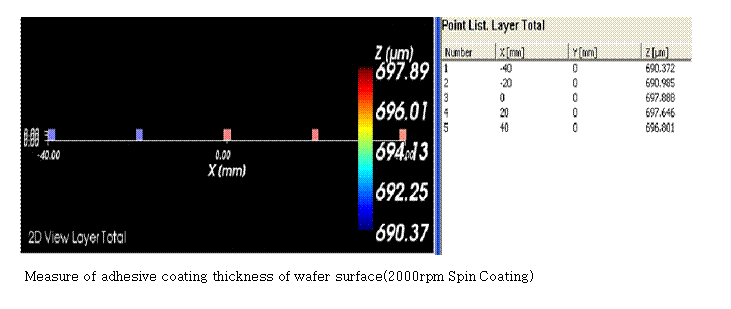

SPA-140 is adhesive for sapphire wafer, spin coating and dry adhesive agent to wafer back side after the Lapping, annealing process. Next, put on the alumina plate (Block) , then dry at 80 ℃ for adhesive. The first step is Diamond Slurry Polishing and the second is Colloidal Silica Polishing. During the first and second step, wafer should not fall apart from the alumina plate. Wafer should easily come off at 100 ~ 120 ℃ after complete polishing .

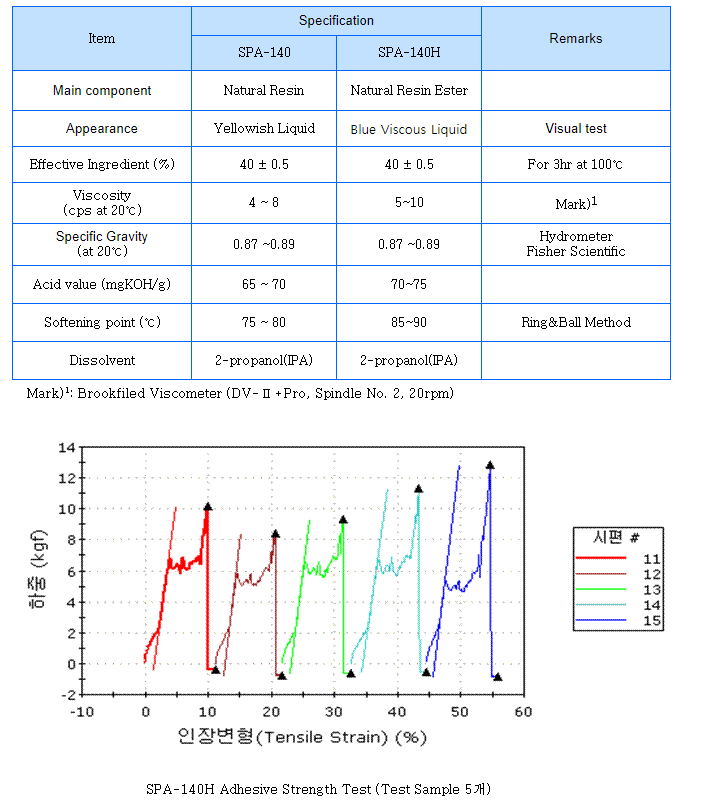

SPA-140H has a higher softening point and strong adhesive strength than SPA-140, has superior adhesive ability without thrust of wafer from the frictional heat in the CMP process of severe condition. This is a blue color and a superior thermal resistance, retains a stable color (no discoloring) over 100℃. The blue coloring enhances visibility after baking to ensure complete wafer spin coating to the Edge of wafer. Leveling is superior during the application of wafer spin coating due to the low viscosity of adhesive.

▶ Physical characteristics