Detergent for Sapphire Wafer

- Sapphire is a crystal boules of aluminum oxide (Al2O3) formed at the 2050℃. Because of the remarkable hardness of sapphires, 9 Mohs scale (and of aluminum oxide in general), sapphire has infrared optical characteristics, superior heat conductivity, stability between low and high temperature similar metal in ceramic material.

● Product Name: : WD-240

- Sapphires are used in semiconductor circuits and parts applications, including infrared optical components, laser parts applications, and very thin electronic wafers, which are used as the insulating substrates of very special –purpose solid-state electronics (most of which are integrated circuits). Specially TV, LED light are growing industry field.

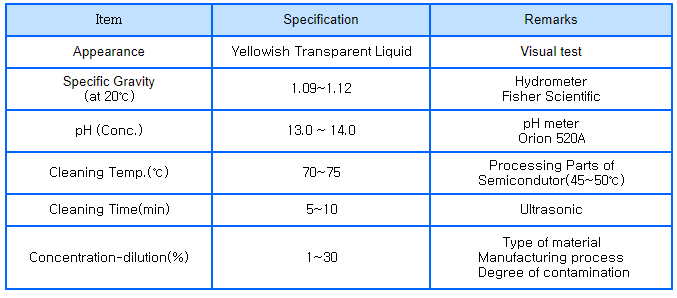

▶ Physical characteristics

▶ Characteristics

1. Superior of detergency due to build metal Carboxylate soapy salt from the chemical reaction of Carboxylic groups (-COOH) of adhesive component which has strong Acid value.

2. Appropriate final cleaning process at the clean room before packing due to preventing re-sticking on the material surface from the formation of stable chelate compound with metal ion which is taboo element on the semiconductor process parts such as Silicon, Quartz, Ceramic include adhesion cleaning.

3. Cleaning available even in Complicated internal structure.

4. Effective for dipping and spray cleaning.

5. No stain from the detergent residue after complete cleaning.

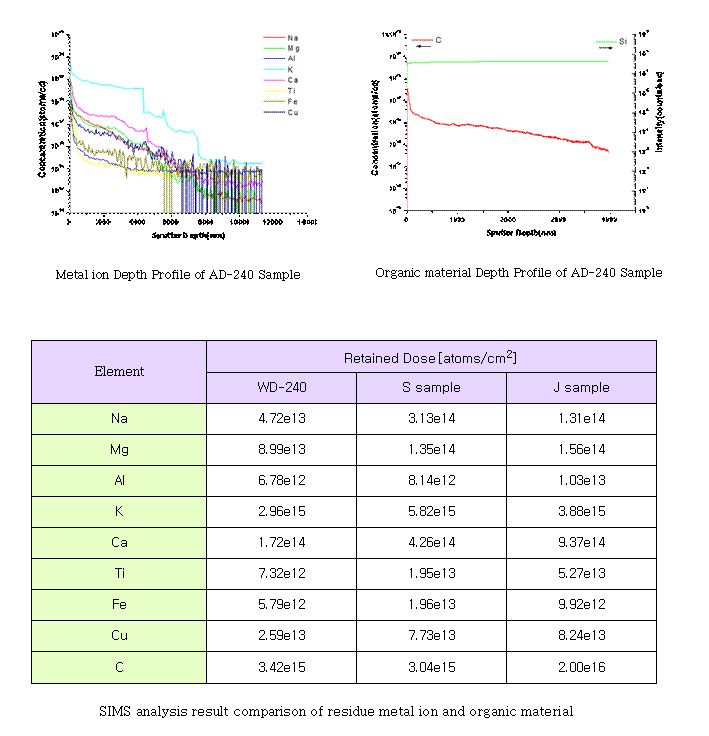

* Evaluation of detergency comparison

- Evaluate detergency after Silicon (semiconductor process parts) cleaning between our product of WD-240 application and two other detergent in same condition for the residue metal ion and organic material test.

Procedure are first emit 1st stage ion light on the sample surface of micro domain, measure generated ppm level of ion differential quantity analyzed by SIMS. SIMS analyze micro-micro element analysis and chemical structural formula, isotope analysis and so on. (SIMS :Secondary Ion Mass Spectrometry)