Processing Fluid for Inorganic Materials

- Inorganic material (silicon, quartz, sapphire, gallium / arsenic) cutting fluid is unlike the normal coolant fluid used in metal cutting machining that use wire sawing methods, SiC slurry maintains an excellent proper viscosity, phase separation and sedimentation prevention of the compressed material, depending on the type and characteristics, as there are many different kinds available.

● Product Name: MCR-741

- MCT (Machining Center) equipment used in processing Silicon, Quartz, Ceramic and others, uses CAD which functions as an exchange installed device. The processing equipment depends on how dozens of tools automatically exchange with the device using CAD MCT. Cubic processing is not normally available but during the MCT processing based on using an apparatus which rotates the four sides. The other way is allowing machining on four sides during one operation, The next material is ready and as soon as the operation is complete, the machine automatically exchanges between completed product and the next raw material to be worked.

NC (control numerically) is one part of the auto system cubic processing available with our product, from NC development processing now is auto system CNC (Computer control numerically) that uses our product also. Recently the rotary grinding process has increased enabling regular thickness of circle material surface processing which our product also supports. While processing MCT and CNC there is centrifugation system which separates the fine powder created during the process from the cut fluid. Our product also provides a superior wetting that makes a fast separation rate from the powder dust and low surface resistance in the case of grinding since it has no centrifugation system.

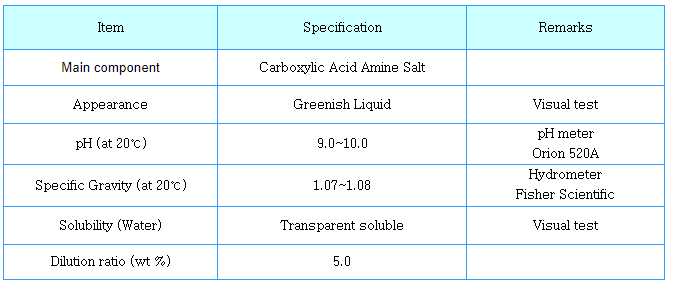

MCR-741 is for silicon, quartz, ceramic and others materials, providing a superior moisture effect, for non-organic material operation processing , this products is a water base cutting fluid for MCT, NC, CNC, rotary grinding and others machines. Mono or di-Carboxylic Acid Amine Salt (C8~12) is the main ingredient.

▶ Physical characteristics

▶ Characteristics

1) Prevents the generation of frictional heat by reducing frictional force between equipment and the material during the process of milling or cutting

2) Reduces the powder dust accumulation with the increased wetting on the surface of the material being processed

3) Provides a fast removal of the powder dust generated during the operation, due to decline surface tension.

4) The results of lubrication, high-pressure, wetting, cooling and cleansing ability is superior in this product.

5) Due to the superior anti-corrosiveness of the product, the processing equipment does not obtain rusting.

6) Due to use in low concentrations, 5% dilution it is very economical.

7) Make soft water during the dilution if water hardness is high concentration, from the kylate action.

8) Irritant is low due to the addition of low volatile amine which lowers the smells

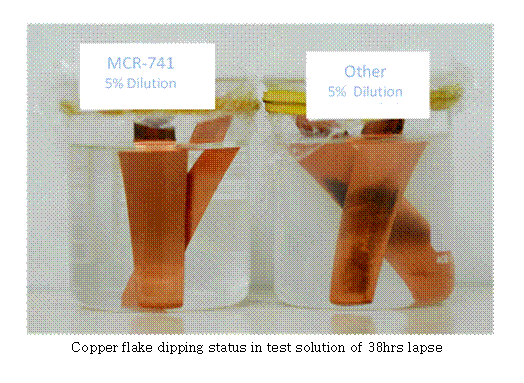

▶ Comparisons of corrosive between MCR-741 and other product.

- MCR-741 and other company’s product diluted 5% Wt (20times), Copper (Cu) (purity:99.999), (Manufacture: Pung San Metal) class 2 each dipping to solution 100mg . covered top of the beaker with Clear Wrap, for 38hrs in a 50℃ Dry Oven, then compared corrosive