Slurry for Back Polishing

● Product name: JINSOL BPS-215

- To achieve delicate microchip products, the silicon wafers have to be completely flat and smooth prior to the next step of imaging circuit patterns on the wafer.

JINSOL BPS-215 is a product used in the finalization process of chip production. When producing wafer chips using a laser sawing process (Laser sawing is limited If the wafer thickness is too large.) The first step after laser sawing involves grinding the Back of a 300㎛ wafer until a thickness of 70~100㎛. Next involves high-precision processing by colloidal silica slurry (JINSOL BPS-215) for the back polishing of the wafer until 9Å of surface roughness is achieved. The slurry particle size is approximately 30~40nm ..

The slurry is used in the polishing process after 20 X dilution with purified water. The slurry will not cause blockage of the supply pipe line during the polishing process. The slurry is non-volatile and will not released colloidal silica particles mists or aerosols.

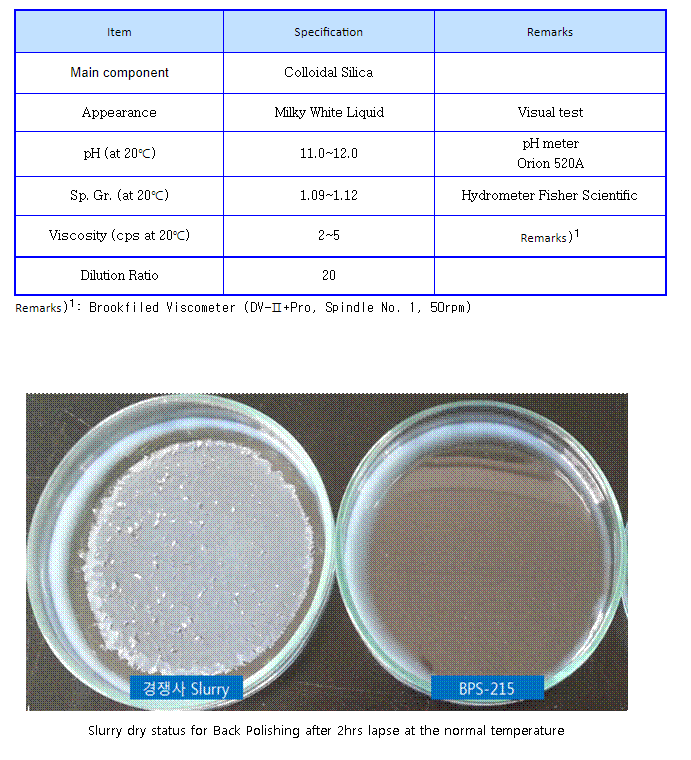

▶ Physical characteristics