Antistatic Agent for Water-borne Paint

- Antistatic agents are compounds used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity generally caused by the triboelectric effect.

● Product Name: PAS-355N

- Water-borne paint is easier to use and dries faster than enamel paint. It is very economical due to being a water-borne paint and also it has low physical properties. Another great feature is that it does not contain volatile organic compounds which reduces the fire danger of using this product.

Other antistatic agents that have been added to water-borne paints to provide this special purpose normally add metal powders, tin surface process into the titanium dioxide surface. This process provided an inorganic antistatic process that is heavy in metal products, very expensive and required a 30-50% mixture of antistatic agents to be added.

PAS-355N is an antistatic agent that uses friendly acrylic and urethane resin as a binder for the water-borne paint and it is added in the paint manufacturing process.

▶ Characteristics

1) PAS-355N does not turn to a gel after being added to the paint.

2) PAS-355N is very compatible with paint and it does not make blooming on the paint surface.

3) Provides an effective baseline antistatic base even when only a small amount of antistatic agent has been added to the mixture (5-10%)

4) This agent does not change the physical characteristics such as, paint adhesion and hardness.

5) Outstanding heat resistant quality.

6) When mixed, this product does not have any lost of color, fade or bleed.

7) Due to the colorless transparences’ of this agent it does not have any affect on colors or non-color such as white paint.

▶ Instruction of use

Mix antistatic agent PAS-355N during the final paint manufacturing process according to the surface resistant requirement.

▶ PAS-355N efficiency assessment

1. Assessment method

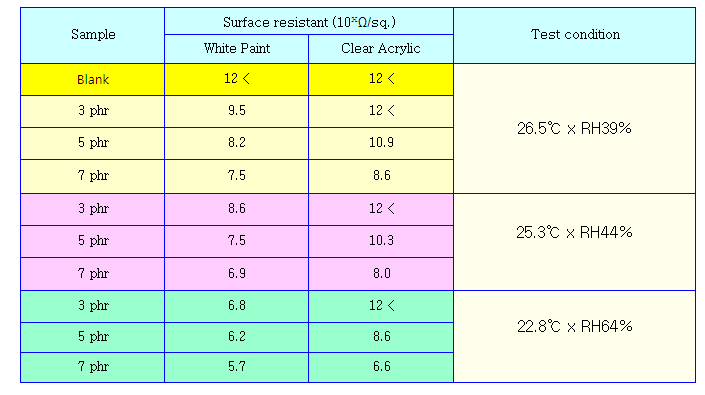

Add and mix PAS-355N to WHITE WATER BASED PAINT and CLEAR ACRYLIC Resin 3, 5, 7phr individually, and then applied coating on to OHP Film and then dry at 50℃ using a Dry Oven for 2.5hrs, then after waiting 24hrs the surface resistant was tested individually.

2. Test results

3. Result and remarks

1) After adding and mixture of PAS-355N to white paint and clear acrylic resin, 3, 5, 7phr individually and dried at 50℃ using a Dry Oven, viscosity of 7phr went up, but none had gelation at 8hrs heating.

2) When PAS-355N is added in the same amount to white paint and clear acrylic resin, it shows a lower surface resistant specific character on White Paint then when applied to Clear Acrylic, test result showed that Clear Acrylic has no antistatic effect at the test level of 3phr even in a condition of RH64%.