Antistatic agent for water base coating

- Antistatic agents are compounds used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity generally caused by the triboelectric effect.

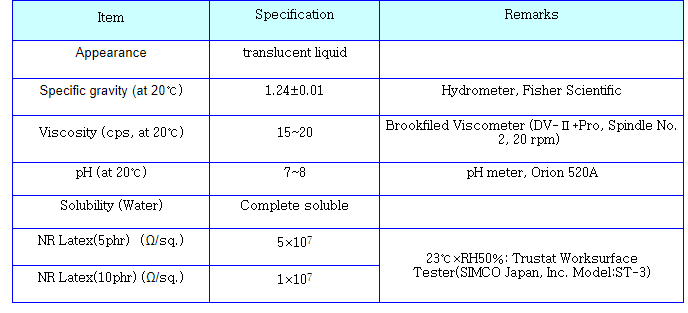

● Product Name: PUL-337

- Water base coating agent uses water as a solvent, the composition of the antistatic agent is surfactant group, if you use this surfactant as an antistatic agent, it will have the form of a gel immediately or if not used as a gel, it will change it’s chemical properties within 24hrs. This is due to the ions containing salt, ion property and/or pH. The specially is applied in gloves which are used in the semi-conduct and electric industry. These gloves are made generally from the sulfur vulcanizing method with natural Latex as a main ingredient, this process leads to bad stability in storage, the composition changes to alkali due to ammonia water, severe gellation due to containing vulcanize and vulcanizing acceleration agent, filler, etc,.

PUL-337 is an antistatic agent for water base coating of item which have a main ingredient of NR, SBR, NBR Latex, Acryl Emulsion and PUD as a coating binder.

▶ Characteristics

1) Does not turn to a gel when added to a water base coating composition

2) With coating agent, it has superior comparability and storage stability

3) Coating composition does not change pH by the antistatic agent

4) Keeps permanent antistatic effect

5) Does not change color because of high heat resistant

6) Does not affect colors or whites

7) When it useing more than 10 phr , you must make a plan of coating composition by selecting higher than actual glass transition temperature (Tg) binder, due to low surface resistance, hardness variation of coating layer and have adhesiveness due to plasticity of antistatic agent.

▶ Instruction of use

Uniformly mix with antistatic agent in accordance with surface resistant of water base coating composition requirement.