Antistatic agent for UV curing

- Antistatic agents are compounds used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity generally caused by the triboelectric effect.

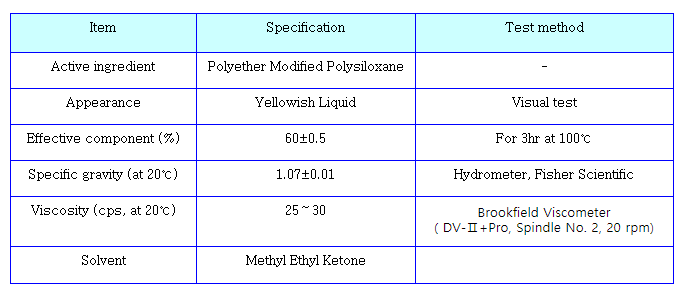

● Product Name: UVAS-364

- UV curing coating resin has a strong mechanical property to include it’s adhesive ability, while providing protection from abrasion and scratching compared to heat curing or other drying coating agents. This product is used in curing coating of PET film which in turn is used in semi-conductor, display or electric parts during the LCD manufacturing process.

UVAS-364 is an antistatic agent used for UV curing acryl adhesive, polyethylene Glycol Diacrylate group UV curing coating.

▶ Characteristic

1) Does not convert to a gelation during mixing process with the coating agent.

2) Transparency in coating layer is not affected by antistatic agent.

3) Curing is not affected in UV (300~500 mJ/cm2) by antistatic agent.

4) Mechanical properties of coating layer is not lowered by adding an antistatic agent.

5) Superior antistatic effect of 109-11 Ω/Sq. RH45% standard.

6) When subjected to heat for dissolvent drying the antistatic agent it does not affect the color (does not turn yellowish) due to it’s heat resistant.

▶ Instruction for use

- Mix UVAS-364 with your required coating agent uniformly for 3-5hrs prior to application to final product based on the required surface resistance of the final manufacture process.