HDF-260R/H

- Two-Parts fast-curing polyurethane waterproofing membrane with high performance, high solids and low odour. It is formulated for application to horizontal, exposed surfaces and provides long-life waterproof protection.

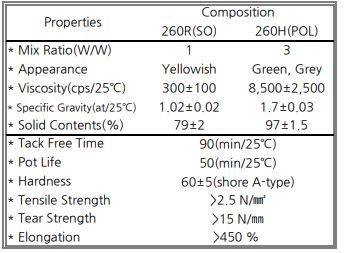

▶ TECHNICAL DATA

▶ Features

* Two-packs, RTV system.

* Fast application withour multi layering.

* Good adhesion to the substrates.

* Good adhesion to the topcoat.

* Good persistence and chemical resistance.

▶ Uses

* General exposed areas for light traffic.

- Roof-deck, walkway, hallway, floor, etc.

* General exposed surfaces.

- Concrete, block, brick, tile, etc.

▶ Color

* Green, Grey

- Custom colors are available.

*Tend to yellowish and become chalking after exposure to UV light. It should be combined with Varo-Top HG for UV-resistance and durability

▶ Coverage

* 1.50kg/mi in 1.Omm dry film thickness on a smooth surface.

* Recommended flilm thickness: 3mm.

▶ Packaging

* HDF 260[R] : 5kg / Steel Pail

* HDF 260[H] : 15kg / Steel Pail

* Mix Ratio(R: H) = 1:3 by weight

▶ Storage

* Use within six(6) after manufacturing date written on the label.

* Store in cool, dry and well-ventilated place.

* Avoid exposure to humidity and UV.

* Avoid contamination by water, alcohol, etc.

* Keep away product from heat, spark and flames.

▶ Surface Preparation

Surfaces must be sound, smooth and free from dust, laitance, oil or other contaminants.

▶ Application - Professional use only.

* Priming

- To inhibit pin-holes and increase the adhesion to the surfaces, porous surfaces should be coated by primer(Varo-BP is recommended) at 0.25Kg/m in 0.1mm dry film thickness.

* Weighing, Mixing and Coating

- Measure each indivisual HDF-260[R/H] membrane Isocyanate and Polyol component accurately by weight into a clean container and mix throughly with an electric stirrer prior to application.

- Please apply product within pot life

- 50(min/250)

- Do not apply product unless concrete has cured at least 28days at 20C and over 80%RH or equivalent. The surfaces temperature and moisture content should be lower than 400 and 6%

- Do not apply product when the temperature is below 50

- Cover the fully dried membrabne by Varo-Top HG R/H for color-fast and endurance

- Please refer to the general guideline for complete information.