HS-300N

- Single component with high performance polyurethane based non-sag joint sealant. It has excellent adhesion to most surfaces including concrete, steel, aliminum, wood, fibre sheet, etc. and provides durable sealing.

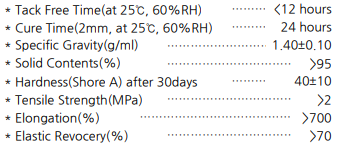

▶ TECHNICAL DATA

▶ Features

* One-pack, moisture curing system.

* Easy, fast application

- No problem with mixing.

* Good adhesion to the surfaces.

* Good elasticity, elongation, restoration.

* Can be painted after curing.

▶ Uses

* General non-exposed sealing: multi-purpose.

- Concrete, steel, block, brick, tile, etc.

- Repairing cracked concrete.

* Tend to yellowish and become chalking after exposure to UV light.

▶ Color

* Green, Off White

▶ Coverage

* Depend on Joint Dimension

▶ Packaging

* Sausage type

- 500ml(700g)/pieces x 20 pieces = 1 carton

- 600ml(840g)/pieces x 20 pieces = 1 carton

▶ Storage

* Use within six (6) after manufacturing date written on the label.

* Store in cool, dry and well-ventilated place.

* Avoid exposure to humidity and UV.

* Avoid contamination by water, alcohol, etc.

* Keep away product from heat, spark and flames.

▶ Surface Preparation

* Surfaces of membrane must be sound, smooth and free from dust, laitance, oil or other contaminants.