HSC-S600P/R

- Two parts, fast curing sealant using polyurea technology. It provides excellent workability, adhesion to most surfaces including concrete, steel, aliminum, wood, fibre sheet, etc. and provides durable sealing.

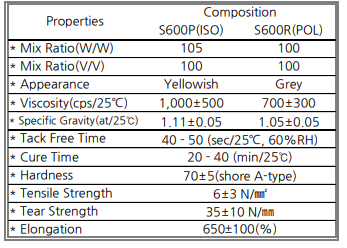

▶ TECHNICAL DATA

▶ Features

* Good workability - Fast curing.

* Simple application by low pressure coating equipment.

* Excellent physical performances and adhesion to most surfaces.

* Eco-Friendly Product -100% solid

▶ Uses

* Control joint - Parking lot, Bridge deck, Airport, Water treatment facilities etc.

- Repairing cracked concrete

▶ Color

* Grey

▶ Coverage

* Depend on Joint Dimension.

▶ Packaging

* HSC-S600P [Isocyanate] : 17kg / Steel Pail

* HSC-S600R [Polyol] : 16kg / Steel Pail

* Mix Ratio ( PR) = 1:1 by volume

▶ Storage

* Use within six(6) after manufacturing date written on the label.

* Store in cool, dry and well-ventilated place.

* Avoid exposure to humidity and UV.

* Avoid contamination by water, alcohol, etc.

* Keep away product from heat, spark and flames.

▶ Surface Preparation

* Surfaces must be sound, smooth and free from dust, laitance, oil or other contaminants.

▶ Application - Professional use only.

* Priming (Recommended)

- Adhesion to the surfaces can be improved by priming(Varo-BP is recommended) at 0.25kg/m in 0.1mm dry film thickness prior to application.

* Applying

- Allow to dry fully before applying.

- Application temperature: 5-400

- Apply HSC-S600[P/R] using low pressure coating equipment.

- Extrude sealant firmly into joint to ensure complete contact on a joint faces.

- Do not use on exposed areas affected by UV

- Painting over the fully dried area is available.

- Do not apply product unless concrete has cured at least 28days at 20C and over 80%RH or equivalent. The surfaces temperature and moisture content should be lower than 400

- Do not apply product when the temperature is below 50

* Recommended Application Equipment

- 2-part Low pressure coating machine.

- Graco E-10