FMT DS SERIES

BENCH TOP FERMENTOR : FMT DS Series

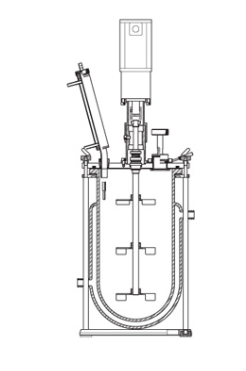

- A model with a jacket-type, double-shell vessel structure that is ideal for the cultivation of plant and animal cells.

Quick coupling and a sliding-type peristaltic pump have been adopted for the exhaust gas condenser.

1. Features

· Precisely controls temperature using a double-shell vessel

· An 8.4"touch screen computer with HMI that can be conveniently operated

· PLC adopted as a main control system

· Loaded with an interlocking control program to enable the cultivation of various conditions

DO interlocking function - Agitation Speed

FEED interlocking function - dissolved oxygen, supply time

PH interlocking function - feed rate, dissolved oxygen

· A controller whose reliability can be guaranteed has been adopted.

· Cylinder borosilicate vessel (Pyrex glass)

· Agitation system: mechanical seal used

· Various nozzles made with precisely processed STS 316L and parts guarantee the highest level of confidence

· Elegant design considered for easy repair and cleaning

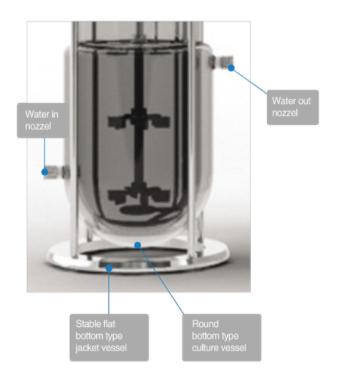

2. VesselType

3. Specifications

· Double shell vessel perfect for cell culture: precisely controls temperature

· Autoclavable double shell borosilicate glass vessel

· 1~14L total volume

· Electro polished STS316L head plate & bottom plate

· Nozzles

-Inoculum port : Flaming (option: Septum nozzle or aseptic inoculation valve)

-Temperature, pH, DO, foam sensor (option : ORP, level, OD sensor)

-Exhaust & condenser

-Agitation

-4 media feeds

-Sampling & harvest (option : aseptic transfer valve)

· Agitation

-Single mechanical seal

-High torque 60 W BLDC motor (30~1,200 rpm)

-3 baffles or more

· Aeration

-Ring sparger (option : 1~10㎛ micro sparger)

-0.2㎛ disposable hydrophobic filter with check valve

· Removable addition bottles support

-Peristaltic pump with tubings

· Impeller

-Rushton type/Pitched blade/Marine blade

· Gas flow

-2 gas control rotameters (option : 4 rotameters or 1 ~ 4 mass flow controller)

-Flow rate

0.3~3 L/min

0.5~5 L/min

0.7~7 L/min

1~10 L/min

1.4~14 L/min

4. Control

· 8.4" or 17" touch screen computer

· 1 to 12 vessels intelligent control

· 16 control loop per vessel

· Temperature control : heating/cooling (option : water chiller)

· pH control : acid/base agent

· Agitation control : 30~1,200 rpm

· DO control : PID cascade control with agitation, feeding and gas flow rate

· Feed control : fed-batch control by time, DO, pH

· 4 pump control : acid, base, anti-foam, feeding easily calibrated pump

· 8 multi trend log data per vessel

· Easily calibrated sensors