ELcoat® AS

- Anti-static coating

- ELcoat® AS is an innovative anti-static coating solution, it could coating on not only all kind of plastic substrates but also even glass and other inorganic materials Include metals with high transmittance and stable resistance, ELcoat® AS typically being applied to FPD parts especially to protective films, releasing film, anti-static panels, windows for mobile devices, etc. with specialized anti-static and anti-dust abilities.

● Products

- ELcoat® UVH 306 : Coating solution for anti-static panel for semiconductor cleanroom / 105~8Ω/■, Solvent resistance, Hardness

- ELcoat® UVH 500R : Coating solution for Anti-static dicing tape / 106~8Ω/■, Solvent resistance

- ELcoat® TA 400 : Coating solution for anti-static tray for module protection / Before forming 104~5Ω/■,

- ELcoat® ASH 600 : Coating solution for anti-static release film / 104~5Ω/■, Solvent resistance

- ELcoat® AS-C7 : Anti-static Coating solution for injection tray / 104~7Ω/■, Spray coating

● Features

- Remarkable optical property

- Excellent anti-static performance

- Stable surface resistance

- Adhesion and processability to various substrate

● Property – PEDOT:PSS Base

Grade | ELcoat® TA

Heat dry type | ELcoat® ASC

Dilution available

(10-30 times) | ELcoat® ASH

Heat cure type | ELcoat® UVH

UV cure type |

|---|

Surface Resistance (Ω/■) | 104~11 | 104~11 | 104~6 | 104~11 |

Haze (%) | < 1.0 | < 1.0 | < 1.0 | < 1.0 |

Transmittance (%) | > 90 | > 90 | > 90 | > 90 |

Pencil Hardness | > B | > B | No nail scratch | HB~2H |

Taping Test | 100/100 | 100/100 | 100/100 | 100/100 |

Coating Method | Gravure & Slot die | Gravure & Slot die

Flow & Spray | Gravure & Slot die | Slot die

Flow & Spray |

Curing Condition (Lab) | 80℃Ⅹ1min | 80℃Ⅹ1min | 130℃Ⅹ3min or

80℃Ⅹ1min + 60℃Ⅹ72hr | 60℃Ⅹ1min →

UV 500mJ/㎠ |

Demand Property | Stable surface resistance | Cost saving, NO migration | Solvent resistance | Good solvent &

scratch resistance |

Durability | Good | Not bad | Good | Good |

Coating property measured with PET film (100㎛)

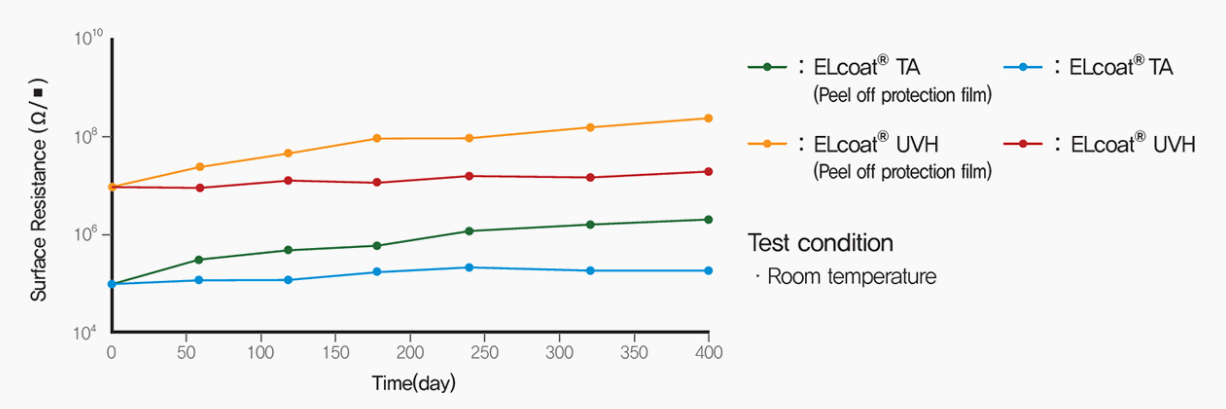

● ELcoat® TA/UVH (Heat dry/UV cure Anti-static coating) - Durability

● ELcoat® ASC (Dilution available anti-static coating) - Dilution ratio

Dilution ratio | 10imes | 20imes | 30imes |

|---|

Surface Resistance (Ω/■) | 105 | 106 | 107~8 |

Haze (%) | < 1.0 | < 1.0 | < 1.0 |

Transmittance (%) | > 90 | > 90 | > 90 |

Taping Test | 100/100 | 100/100 | 100/100 |

Available Dilution Solvent | Ethanol, Ethanol/Water(1:1), IPA/water(1:1)…. |

Coating method | Gravure & Slot die & Flow & Spray |

Drying condition (lab) | 80℃ Ⅹ 1min |

Coating property measured with PET film (100㎛)

● ELcoat® ASH (Heat cure type Anti-static-coating) - Solvent Rubbing Test

Solvent | Initial

Surface resistance (Ω/■) | After rubbing (500gf, 10times)

Surface resistance (Ω/■) | After rubbing (500gf, 10times)

Surface resistance (Ω/■) |

|---|

IPA | 104.6 | 105.0 | 106.4 |

MEK | 104.6 | 105.1 | 108.0 |

TOL | 104.6 | 104.9 | 107.4 |

Coating property measured with PET film (100㎛)