F.E.P Tube

What is F.E.P(underground pipe)?

The development of modern industries and the over-concentration of cities is increasing demand for enhancing safety, securing more space and achieving finer views in urban areas, industrial areas and areas next to the roads, which is causing the trend of laying wires and communication cables underground. Previously all the underground conduits used hume pipe, steel pipe or PVC pipe but these conduit line were all direct tubes. In addition, the pipe lengths are short requiring many connections and they are heavy which meant it has disadvantage of difficulty in building as well as extra cost in construction cost due to labor shortages and loss resulting from delay of working terms.

What solved all the mentioned difficulties was F.E.P. underground pipe, proudly developed by Duksung Industry.

F.E.P was treated with unique spiral wave and hence overcame weakness of surface strength in the previous polyethylene pipe and the strength was few times higher and had appropriate level of pliability making it efficient in construction.

F.E.P, being flexibility, strong and ease to operate with, it was introduced as the replacement to the previous pipe and have achieved great sales results in advanced countries. Having an outstanding ease of operation and surprisingly cost effectiveness, it will meet all clients' requirements and more.

Characteristics and usage

▶ Good Flexibility

Due to its wave treatment, it can be bent with ease and can be used in construction where it needs to avoid obstacles.

Due to the low coefficient of friction and lead-in cable line is already placed in the pipe; cable can be "led-in" with ease. Hence, the distance between manholes can be long.

▶ Strong and Safe

Due to its wave treatment, the high surface strength can withstand from heavy load from laying under the ground. In addition, its flexibility and its high intensity in internal pressure make it safe in natural disasters such as earthquakes, ground subsidence, etc.

It is made out of PE and hence it is relatively much lighter than copper or hume tubes and it is easy in transportation and installation.

▶ Longer unit length

The unit length is longer, consisting of less connection parts and hence make significant cost saving in human resources in installation and reduction in working terms.

when the above advantages are combined, it will result in a great economic value due to improvements in operation efficiency, reduction in working terms, and reduction in manholes, compared to the previous pipes.

▶ High reliability

As an insulator, it has outstanding insulating properties, making ideal as electric wire pipe.

▶ Outstanding corrosion resistance and durability

It is semi-permanent because it has strong chemical resistance against acid, base or oil so it is not damaged by chemicals and does not corrode in sea water or in swampy area.

Usage of F.E.P pipes

- Golf Course

- Residential land development

- Park development

- Park development

- Apartment development

- School and sports facilities development

- Installation of street lights

- Replacement of decorative electric poles in urban areas underground construction

Specification

Name | Inside Diameter (mm) | External diameter (mm) | Pitch (mm) | Length (m) | Standards

(External diameter x width) |

Basic dimensions | Permissible level |

30 | 30±2.0 | 40 | ±2.0 | 10±0.5 | 100 | 1.2×0.55 |

40 | 40±2.0 | 53.5 | ±2.0 | 13±0.8 | 100 | 1.5×0.6 |

50 | 50±2.5 | 64.5 | ±2.5 | 17±1.0 | 100 | 1.6×0.65 |

65 | 65±2.5 | 84.5 | ±2.5 | 21±1.0 | 100 | 1.7×0.7 |

80 | 80±3.0 | 105 | ±3.0 | 25±1.0 | 100 | 1.8×0.7 |

100 | 100±4.0 | 130 | ±4.0 | 30±1.0 | 60∼100 | 2.0×0.75 |

125 | 125±4.0 | 160 | ±4.0 | 38±1.0 | 50 | 1.7×1.1 |

150 | 150±4.0 | 188 | ±4.0 | 45±1.5 | 50 | 1.8×1.2 |

175 | 175±4.0 | 230 | ±4.0 | 55±1.5 | 30 | 2.3×1.5 |

200 | 200±4.0 | 260 | ±4.0 | 60±1.5 | 30 | 2.3×1.2 |

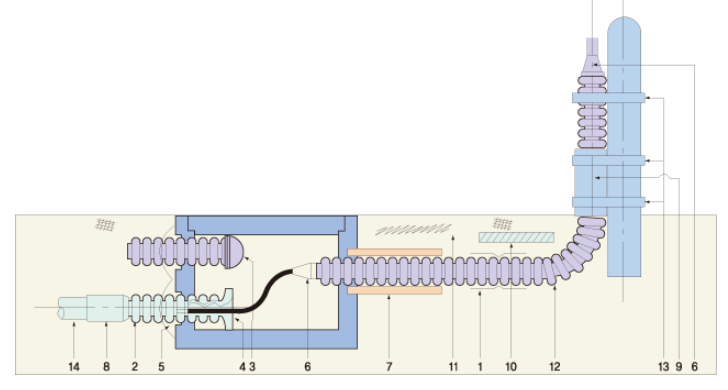

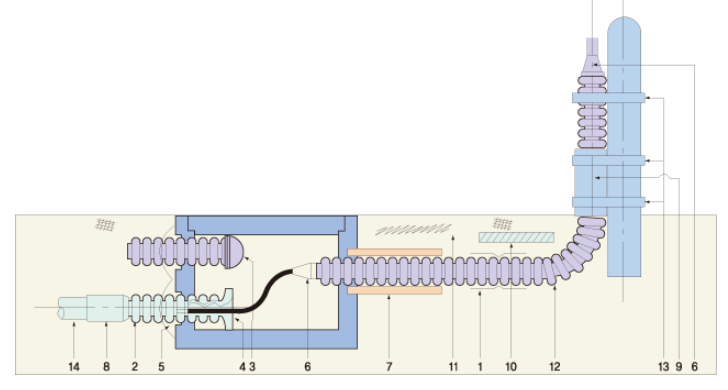

Related products and part names | Purpose | Specification |

1. Straight Connection Sleeve | When connecting F.E.P pipe (underground pipe) | Standards following F.E.P pipe (underground pipe) |

2. Related Connection Pipe | When connecting F.E.P pipe (underground pipe) with related pipes | Type based on joining connecting pipe |

3. Bell Mouse | When finishing face wall of manholes | Standards based on F.E.P pipe (underground pipe) |

4. Plug for Emergency pipe | | Standards based on F.E.P pipe (underground pipe) |

5. Waterproof material for the face wall | When treating the face wall in the manholes for waterproof | mixture of different material |

6. Waterproof material for conduits | When treating the face wall in the manholes for waterproof | 1조용, 수조용에 대한 F.E.P Tube (지중전선관)의 규격 |

7. Shock-absorbing pipe | When reinforcing external wall of manholes | |

8. When attaching Clamp | monopole | Standards based on F.E.P pipe (underground pipe) |

9. Nacre band | When attaching F.E.P pipe (underground pipe) to electric pole | for below Ø60, above Ø80 |

10. Epotite | in case of restoration of ground to preventative exterior | for below Ø65, above Ø80 |

11. Marking Tape | in case of restoration of ground to protect the exterior | thickness 20mm × 30mm × length 1,700mm |

12. F.E.P pipe (underground pipe) | | thickness 0.15 mm × 150mm × length 50mm |

13. Granular protective pipe | in case of restoration of ground to protect the exterior | thickness 20mm × 30mm × length 1,700mm |

14. Related pipes | | |

Construction Method

01. Determine caliber of the pipe The caliber of the pipe are determined by economic principles based on the voltage of the cable, exterior of the electric wire, allowable electric current, the conditions of construction.

02. Construction site Determine depth of the excavation : where there is concern of pressure due to vehicles and other heavy materials, over 1.2 me and other places over 0.6 m are required for laying underground. (Clause 144, standards on the electric installation) Determine width of the excavation: If the excavation depth is over 1 m, the slope should be 1:0, and the width should have over 150mm on both sides of the installed conduit. In case of installation of retaining of earth, it should be over 200 mm. Before construction, eliminate as much protrusions for the bottom part of the conduit and eliminate the unevenness on the ground

03. Installation

When unloading the F.E.P pipes at least 3-4 workers should be involved and should be installed in the way the route was excavated. The installation should be carried out with minimum influx of impurities. The connection of the pipe should be done by 2-3 people holding on both sides and the when tape is applied sufficient amount should be spread out to prevent occurrence of air holes. When applying more than 2 circles, the appropriate space between the conduits should be maintained.

04. Method to maintaining appropriate space when installing perforated conduits (Use of Spacer)

To maintain appropriate space when installing perforated conduit, a spacer should be used. Without the use of spacers, the space between the conduits cannot be maintained and there is a risk that conduits become entangled. Due to contact between conduits, the loss of allowable electric current can be up 20% and due to the rotation of e pipe because of the cable. From this point of view, a spacer should be used. When there is reflection over 15° or when the place is so narrow that the space between the conduits cannot be maintained then the same body concrete should be applied to protect the conduit. And when low current electric wire or water pipe is approaching or crossing over, there should be fireproof partition wall between them, over 30cm for high and low voltage and over 60cm for very high voltage. (Clause 149, standards on the electric installation). When low voltage, high voltage or very high voltage underground electric line is approaching or crossing over, in case of below 30 cm, there should be fire protective covered cables should be used in as underground wire and fire proof partition walls should be installed.

Inside diameter of F.E.P pipe | A.B | C | D |

Ø30, Ø50 | 50mm over | In case of over 0.6m of pressure, over 1.2 regardless of the regulations | 100mm over |

Ø80, Ø100, Ø125 | 70mm over | 150mm over |

Ø150, Ø175, Ø200 | 100mm over | 200mm over |

05. Re-filling Using the standard test rod, after testing the caliber, re-filling should be performed After re-filling with sufficient sand and soil and pack in with water in order to prevent future subsidence.

06. Conduit caliber testing

After installing the conduit, to check for conduit, use the following test rod to check if the conduit is okay, using the test rod with the following caliber

(Unit : mm) |

Conduit Standard | 30 | 50 | 80 | 100 | 125 | 150 | 175 | 200 | External caliber

of the test rod | 20 | 40 | 60 | 80 | 105 | 130 | 155 | 180 | the length of the

test rod | 400 | 600 |

|

07. Methods on attaching fixed element to the F.E.P pipe . Use of shock absorbing pipe: Use strong iron pipe, 5% bigger in external of the F.E.P being used and bury with the F.E.P when applying concrete and install using mortar after concrete is poured.

. Conduit Sealing Gasket: A product that meet with Korean Electric Power Corporation material specification, it should be installed before on manholes or fixed element. Using F.E.P pipe or related pipes, they should be connected and the complete the construction.

. Use of clamps (When connecting with other connection box) : F.E.P pipe and other connecting material (electric outlet box, electric supply box, etc) are connected, use clamp and plastic packing in installation of each box.