CD, CD-P Tube

What is CD tube and CD-P tube?

As the modern society is becoming more advance and more diversified, the same changes occur in the construction of electric apparatus. With the recent development of construction, the related electric constructions have also experienced significant development. And the construction factors such as construction costs, the period of construction were a big burden on the total completion cost.

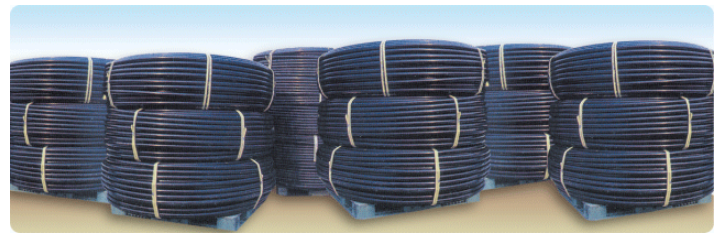

Hence, there was a demand for more cost effective electric tube than previously constructed metal pipes, pliable tubes made out of metal, plastic conduits and buried cables. Considering these factors, we developed updated conduits suitable for our domestic environment based on what was used in Europe for last 10 years and also being used in Japan, which are far more outstanding than its predecessors. Its length is between 30m and 100m, it is light, it has high pliability and relatively cheaper. This can save the construction cost and reduce air holes and also east for construction.

Hope we can open the new chapter in the construction of electric apparatus with newly developed Pliable Plastics Conduits (P.P.C)

Characteristics

▶ Outstanding pliability

Due to its pliability, there is no need for tools such as bander or torch lamp, and ease in piping operation.

▶ Determine caliber of the pipe

Because the inside of the conduit is CD-type, there is less coefficient of friction, it can be inserted with ease for 3 right angles or in case of over 30m piping.

▶ Ease of cutting

Made out of plastic, it can be easily cut with electrician's knife (or a saw).

▶ The tube length is long

Since the unit length is long, there is less connection parts and there is cost saving in coupling.

▶ Ease of transportation

It is made in rolls and light so it can be easily transported and handled even in difficult construction locations.

▶ Almost no dew condensation

Compare to steel pipes, there is much less dew condensation so it be used below 0 degree.

▶ Perfect connection joints

Our firm is a KS certified production firm, manufacturing one-touch connection joints such as connectors, couplings, con-sleeves and end-covers etc. And our connection joints can be perfectly applied not just to our electric pipes but wiht pipes manufactured by other firms.

CD tube and CD-P tube usage

- Flip-flop wall's inside fire-protective piping

- non-obtrusive fire-protective piping for fire fighting

Specification

▶ CD tube

ㆍ KSC 8454

Name | Inside | External diameter (mm) | Length (m) | |

Basic | Permissible | |||

16 | 15.2 over | 21.0 | ±0.3 | 100 |

22 | 20.9 over | 27.5 | ±0.5 | 100 |

28 | 26.7 over | 34.0 | ±0.5 | 100 |

▶ CD-P tube

ㆍ KSC 8454

Name | Inside | External diameter (mm) | Length (m) | |

Basic | Permissible | |||

14 | 2.1 over | 19.0 | ±0.3 | 4(120) |

16 | 2.1 over | 21.0 | ±0.3 | 4(120) |

22 | 2.2 over | 27.5 | ±0.5 | 4(90) |

28 | 2.7 over | 34.0 | ±0.5 | 4(90) |

36 | 3.1 over | 42.0 | ±0.5 | 4(90) |

42 | 3.6 over | 48.0 | ±0.5 | 4(60) |

54* | 4.0 over | 60.0 | ±0.8 | 4(40) |

70* | 4.0 over | 76.0 | ±0.8 | 4(40) |

82* | 5.3 over | 89.0 | ±0.8 | 4(40) |

100* | 5.0 over | 114.0 | ±0.8 | 4(40) |

Construction Method

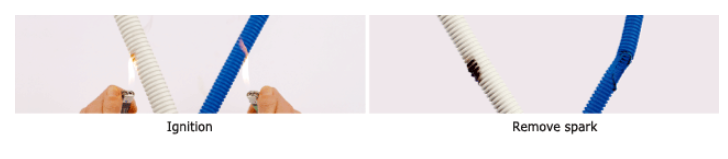

01. Cutting It can be easily cut with knife carried by electrician or the heavy duty cutter which can be readily bought in the market, so that it is perpendicular to the wooden axis.

02. Connecting with other parts CD pipes which is cut perpendicular to the wooden axis can be easily inserted with a light push along with ringshaped parts and will be connected with ease.

X One-Touch type (CD pipe parts)

- Loosen the lid once or twice - Apply CD pipe on the lid level in perpendicular position and push it in all way with some force - Fix it by closing the lid

03. Angular Change The pipe can not be bent 6 times than the pipe's internal caliber. Except when it is below 22mm and in case of special construction structure, it can be bent as long as it is not deformed.

04. Piping Method

The length of piping

Piping between outlet box and between apparatus should not exceed over 3 angular change or 30m. If this limit is exceed, the Pull Box should be installed in an appropriate position.

The space between the connection supports for pipes

The space between connection supports should be 0.5m for first grade steel and 1m for second grade steel. Except, around box, coupling and normal areas, at least 0.3m connection support should be provided.

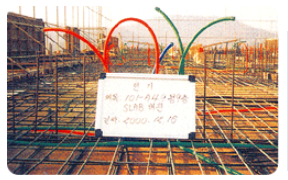

Concentrated Piping

When there is a concentrated piping as in panel board or in main lines, etc the sufficient concrete mortar should be around the pipe without compromising its strength. There should be over 30mm space between them in piping.

Cross-piping in case of second grade steel

Where the steel is crossing at top and bottom of the second grade steel, in order to prevent pressure by the steel, there should be space with the steel when piping.

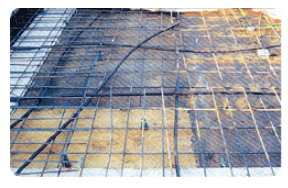

Crossways piping inside walls

If possible, the pipes should follow the steep pipes and since there could be shocks applied on CD pipes when pouring concrete, try to avoid crossways piping. Except, in case of crossways piping, apply 0.5m space in support connection.

Foliated piping (block wall parts)

When laying CD-pipes, in order to prevent bending or falling down, it should be strengthened and supported by steel and board, etc. Especially, the normal area must be completely united.